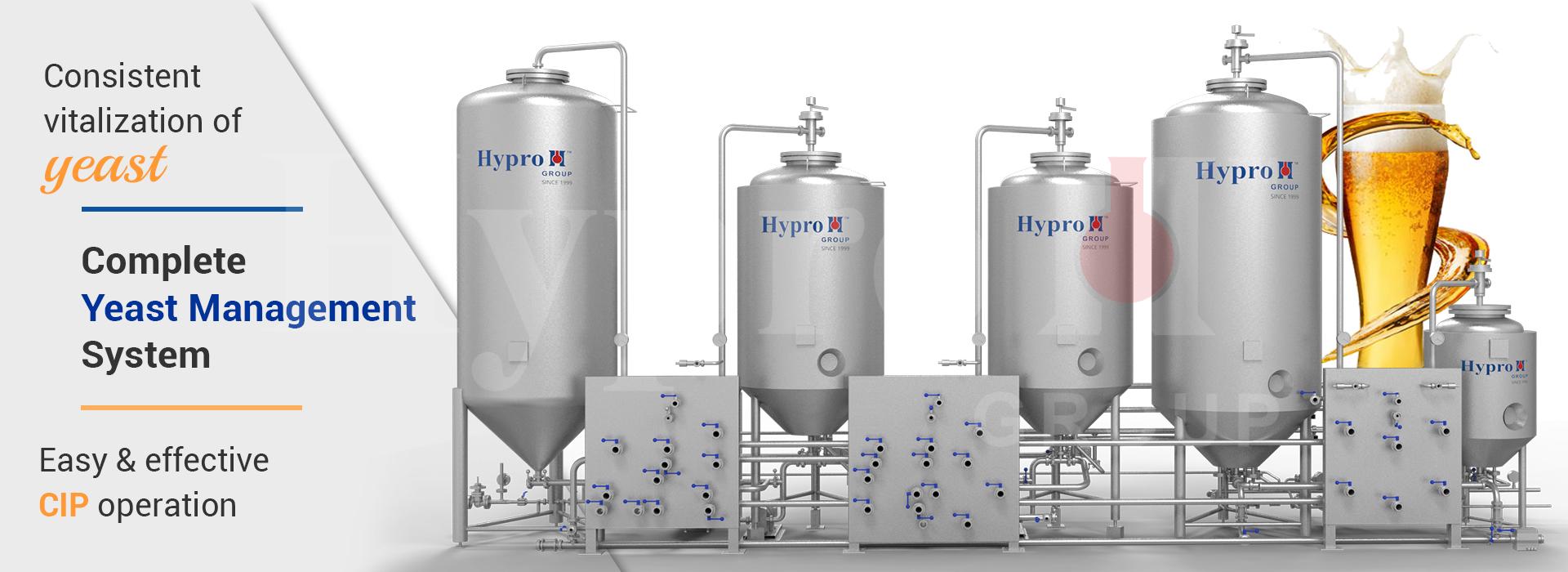

Sistemụ Njikwa Yeast

emebere ya na akụkụ ịdị ọcha dị ka a na-elekwasị anya

Hypro ngwọta zuru oke maka nchịkwa Yeast na nsonye Usoro Mgbasa Yist, Nchekwa & Pitching Systems Ejiri akụkụ ịdị ọcha mee ya dị ka mgbado anya ma na-enye Brewer osisi na ihe enyemaka ya nke nwere ike bụrụ CIP nke ọma ma na-egbochi mmetọ ya. Nke Sistemụ Nchekwa Yist na-akwado ya na mkpali na obere ọsọ iji zere shiee mebiri emebi sel yist. A na-enye ọkwa gravimetric dị ka ọkọlọtọ.

Ngalaba Mgbasa Yist

Onye na-agbasa yist nwere jaket uzuoku na shei & jaket glycol na cone. ọ nwekwara otu ọdụ ụgbọ mmiri maka ikuku oxygen na-aga n'ihu. Ngwakọta tankị elu nke propagator nwere otu valvụ oghere nke nwere ike CIP na otu valvụ nchekwa nrụgide maka nchekwa nke tank. A na-etinyekwa ngwaọrụ bunging na ahịrị CIP nke mgbasa ozi.

Na-esonụ mgbakwasị propagating yist omenala-adị mkpa

- Yist na-ebuli ma gbasaa nje ahụ na wort

- Àgwà iko iko na-agbanwe n'ihi mmụgharị mkpụrụ ndụ ihe nketa

- Mbelata na viability na ike nke yist ka oge na-aga ma na-atụgharị.

- Selụ nwụrụ anwụ na-enye proteases na ndetu ụtọ na-achọghị na biya.

- Ịka nká nke yist na-eme ka ọ dị nwayọọ na ọnụego ọmụmụ.

- Ịka nká nke yist na-ebute mgbanwe n'elu cell na omume flocculation.

- Ịka nká nke yist na-akpata mgbanwe na omume metabolic.

- Ịka nká nke yist na-ebute mmụba n'ozuzu na nha cell

Obere nke ya bu 1gm nke yist ka agwakọta ya na wort nwere ike ndọda. echekwara na flask maka ụbọchị 6 ruo 7 n'ihu ikuku oxygen. Aeration bụ usoro na-aga n'ihu. A na-echekwa okpomọkụ na 18-20 Celsius C. Mgbe ahụ, nkwusioru yist sitere na flask Carlsberg na-ejupụta n'ime ihe na-agbasa ma jiri nwayọọ nwayọọ gwakọta ya na wort ọhụrụ ka a na-eme ya & homogenized - ruo mgbe a ga-enweta ihe yist achọrọ na ntinye mkpụrụ ndụ achọrọ.

Onye na-agbasa yist bụ ma ọ bụ a otu ogbo ma ọ bụ abụọ nkebi. Emebere usoro ntụ oyi na kpo oku Yiast ka akọwapụtaburu wort mpịakọta si otú ahụ na-enyere aka igba ogwu nke wort na ngwa ngwa jụrụ oyi. Maka mgbasa nke yist, a na-eme ka onye na-agbasa ya na ikuku na-adịghị mma site n'iji sparging n'ime arịa ma ọ bụ n'èzí mgbe a na-ekesa ya. Internal Air sparger bụ ụdị a na-ewepụ ngwa ngwa nwere CIP/SIP. Iji mee ngwa ngwa na ịkwalite mgbasa, a na-ekesa wort n'ime arịa ahụ.

A na-agbasa yist maka 7 gaa na 8 ụbọchị na temp 18-20 ogo c. nke mere na iji hụ na mgbasa nke yist kpamkpam ike ndọda nke yist na-enyocha kwa mgbe. Mgbe ike ndọda na-abịa na nkịtị 16-14-ogo Plato wee bufee ya na tankị nchekwa ihe iko achịcha. Maka ịnyefe yist, a na-eji mgbapụta lobe. A na-enyekarị mgbapụta a na njikwa ugboro ugboro.

- Ihe tankị cylindroconical zuru ezu na Shell, efere n'elu, na cone nke ala.

- Jaketị kpo oku & oyi akwa n'ụdị cone na akụkụ shei.

- Jaketị cone bụ maka ngwa kpo oku uzuoku & mkpuchi shei bụ maka ngwa glycol jụrụ oyi

- Otu akụkụ jụrụ oyi na shei nwere njikwa mgbanyụ ọkụ yana otu mpaghara kpo oku na cone ala nwere njikwa ngbanwu/ gbanyụọ

- Akụkụ abụọ jụrụ oyi na shei & cone nwere njikwa gbanyụọ.

- 1 Micro-ọdụ ụgbọ mmiri & 1 Membrane ụdị Keofitt na-eme valvụ nlele na - shrouds.

- Tank nwere jaket na-ajụ oyi na shei na akụkụ cone. A na-egosi okpomọkụ nke tank site na ndị na-ebugharị okpomọkụ dị na shei.

- A na-etinye valvụ njikwa ọkụ na / gbanyụọ maka tank iji chịkwaa okpomọkụ nke tank. valvụ ndị a ga-emeghe ma ọ bụ mechie iji nweta ọnọdụ okpomọkụ atọrọ na profaịlụ/akpaaka mode. A na-enyekwa ihe mgbanyụ ma ọ bụ gbanyụọ akwụkwọ ntuziaka nke enwere ike ịrụ ọrụ site na ihuenyo.

- Enwere ike ịme ọnọdụ okpomọkụ & gbanwee dị ka achọrọ na HMI maka ikpo ọkụ na ngwa oyi n'oge okpomọkụ ọkụ / Glycol jụrụ oyi.

- A na-enye ndị na-ebugharị nrụgide n'elu & ala nke ga-edepụta dị ka nrụgide dị iche.

- A ga-atụgharị ụkpụrụ ndị a na-akpaghị aka ka ọ bụrụ mpịakọta site na iji mmemme larịị-olu enyere na sistemụ. Nke a ga-egosi oke ọgụgụ ziri ezi n'ime arịa

- A na-enye mgba ọkụ dị elu / dị ala iji zere ọkwa efu & njupụta nke sistemụ

Ngalaba Nchekwa Yist

A na-echekwa yist na-agbasa n'ime tankị nchekwa yist ruo ọtụtụ ụbọchị. Ekwesịrị idobe okpomọkụ na ikuku. A na-enye jaketị jụrụ oyi na shei iji mee ka yist jụrụ oyi ruo ogo 8 Celsius. ọ nwekwara aerator mgbakọ maka na-aga n'ihu na-enye oxygen, ugboro ugboro recirculation na-eme maka homogenization.

- Ihe tankị cylindroconical zuru ezu na Shell, efere n'elu, na cone nke ala.

- Ụdị jaket jụrụ oyi na cone na akụkụ shei.

- Jaketị cone na mkpuchi shei bụ maka glycol jụrụ oyi.

- 1 Micro-ọdụ ụgbọ mmiri & 1 Membrane ụdị Keofitt na-eme valvụ nlele na - shrouds.

- Tank nwere jaket na-ajụ oyi na shei na akụkụ cone.

- A na-egosi okpomọkụ nke tank site na ndị na-ebunye okpomọkụ dị na shei

- A na-etinye valvụ mgbanyụ ọkụ / gbanyụọ ọkụ maka tank iji chịkwaa okpomọkụ nke tank.

- valvụ ndị a ga-emeghe ma ọ bụ mechie iji nweta ọnọdụ okpomọkụ atọrọ na profaịlụ / akpaaka mode.

- A na-enyekwa ngwa ịgbanwu/ gbanyụọ akwụkwọ ntuziaka nke enwere ike ịrụ ọrụ site na ihuenyo.

- Enwere ike ịme ọnọdụ okpomọkụ & gbanwee dị ka achọrọ na HMI maka ikpo ọkụ na ngwa oyi n'oge okpomọkụ ọkụ / Glycol jụrụ oyi.

- A na-enye ndị na-ebugharị nrụgide n'elu nke ga-achọpụta nrụgide.

Ngalaba ịkpakọba yist

Yist pitching pụtara mgbakwunye nke yist na wort wee si otú ahụ malite gbaa ụka. Ihe mgbakwunye yist bụ 15 ruo 30 nde sel yist / hl wort. Ọnụọgụ ụda ahụ na-enwe mmetụta dị ukwuu na oge fermenting na ihe ọkụkụ yist. Ka ọ̀tụ̀tụ̀ ụda olu dị elu, ka oge ịgba mmiri na-adị mkpụmkpụ n'otu oge ahụ, a pụkwara iweta ihe iko achịcha ndị ọzọ.

Site na tankị na-echekwa yist, a na-atụba yist na wort dị jụụ na ikuku. A na-eme mkpọtụ yist site n'enyemaka nke mgbapụta lobe site na ijikọ eriri mgbapụta mgbapụta na ebe nchekwa nchekwa yist na eriri na-ewepu na ahịrị wort. Ọnụ ọgụgụ nke yist a ga-eji usoro nlegharị anya na-achịkwa. Ma ọ bụ enwere ike tụọ ya site na sel lode / mita eruba na tankị nchekwa.

- A na-enye ngwongwo ngwongwo na tank iji mara ịdị arọ Yeast Tank & otu ahụ ka a ga-eji tụọ ọnụ ọgụgụ yist. Nke a ga-egosi ọgụgụ ziri ezi nke yist n'ime arịa ahụ.

- A na-enye ngbanwe ọkwa dị elu / dị ala iji zere ọkwa efu & njupụta nke sistemụ.

- A na-enye mgbasa ozi yist /Cum pitching na tankị yist tom pitch na yist na wort ahịrị site na iji okirikiri akpaghị aka akọwapụtara na mmemme. hụ na ejikọrọ na swing niile.

- A na-anakọta yist site na unitank site na mgbapụta yist cropping & echekwara na tank nchekwa yist.

- Mgbapụta mgbapụta CIP ga-arụ ọrụ dabere na nhọrọ okirikiri akọwapụtara n'ime mmemme n'oge CIP nke tankị.

Ọ ga-amasị anyị ịhụ gị na mgbasa ozi ọha!

Ntụle kacha mma maka imewe ịdị ọcha

Osisi Mgbasa Yist & Ngwa Nchekwa Yist na-eji SS 304 L ihe na elu na-agwụ agwụ ka <0.6 uRa na anyị akpaka polishing igwe. A na-eji tankị ahụ mee ihe nchekwa nchekwa CIP; ọkwa akụrụngwa zuru oke maka mmepụta na-agbanwe agbanwe jikọtara ya na Akpaaka dabere na PLC. Nhazi na owuwu nke ụgbọ mmiri na pipework jikọtara ya na mmetọ enweghị ike ime. Ọkụ na-enye CIP site na ọkwa na-arụ ọrụ na cellar ruo n'elu tank nke a na-esi na mkpuchi. A na-enye ubube maka ịnweta ihe ndị dị n'elu tank. Pịpụ usoro ịdị ọcha, akwa valvụ urukurubụba ebe achọrọ na OD dabere na ihe SS 304 maka Wort, Yeast, CO2 & ikuku ikuku, CIP S/CIP R.