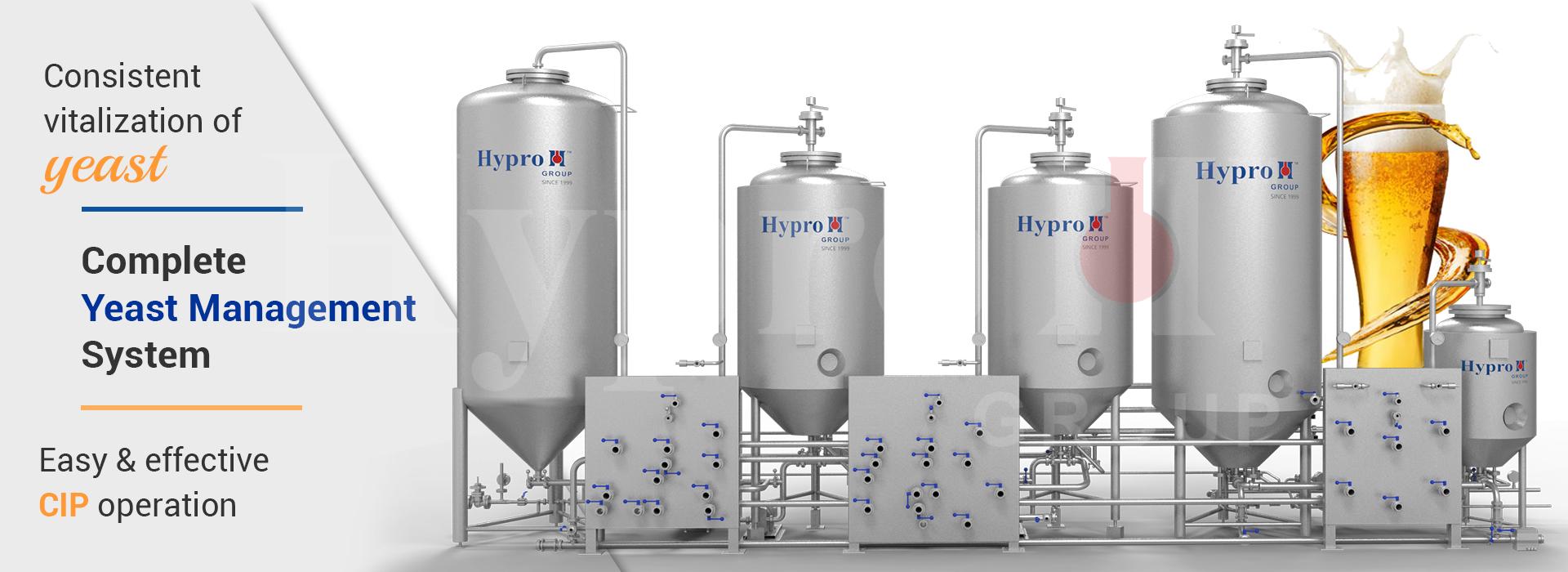

Yeast Management System

designed with hygienic aspects as a focus

Hypro complete solution for Yeast Management including Yeast Propagation, Storage & Pitching Systems are designed with hygienic aspects as a focus and offer the Brewer a plant and its ancillaries which can be effectively CIP and keep contaminations at bay. The Yeast Storage Systems are equipped with agitation at low speeds to avoid shear damage to the yeast cells. Gravimetric pitching is provided as a standard.

Yeast Propagation Section

Yeast propagator has the steam jacket on shell & glycol jacket on the cone.it also has one aeration port for the continuous oxygen supply. Tank top fittings of propagator consist of one vacuum valve which is CIP able and one pressure safety valve for the safety of the tank. The bunging device is also installed on the CIP line of the propagator.

On the following grounds propagating yeast cultures become necessary

- Yeast picks up and spreads the infection to the wort

- Yeast character changes due to genetic mutation

- Reduction in viability and vitality of the yeast over time and re-pitching.

- Dead cells contribute proteases and unwanted flavor notes to the beer.

- The aging of yeast causes a slowing down in the rate of reproduction.

- The aging of yeast causes changes to the cell surface and flocculation behavior.

- The aging of yeast causes changes in metabolic behavior.

- The aging of yeast results in a general increase in cell size

A small quantity i.e. 1gm of yeast is mixed with wort having normal gravity.ie 16-14-degree Plato, then it is stored in a flask for 6 to 7 days in presence of oxygen. Aeration is a continuous process. Temp is to be maintained at 18- 20-degree c. Then yeast suspension from a Carlsberg flask is filled into the propagator & gradually mixed with fresh wort while it is aerated & homogenized – until the desired yeast quantity with the requested cell concentration is obtained.

The Yeast Propagator is either a single stage or two stages. The Yeast Propagator cooling and heating system are designed to the pre-defined wort volumes thus facilitating sterilization of wort and its rapid cooling. For the propagation of yeast, the propagator is aerated with sterile air by way of sparging inside the vessel or externally during circulation. Internal Air sparger is an easily removable type with CIP/SIP. To accelerate and promote propagation the wort is circulated within the vessel.

Yeast is propagated for 7 to 8 days at temp 18-20-degree c. so that to ensure the propagation of yeast completely gravity of yeast is checked on a regular basis. When yeast gravity comes to normal 16-14-degree Plato then it is transferred to a yeast storage tank. For the transferring of the yeast, a lobe pump is used. This pump is generally provided with a variable frequency controller.

- Cylindroconical tanks are complete with Shell, top dish, and bottom cone.

- Heating & Cooling jacket embossed type on cone & shell portion.

- Cone jackets are for steam heating application & shell jackets are for glycol cooling application

- One cooling section at the shell with on-off control and One heating zone on the bottom cone with On/Off control

- Two cooling sections at shell & cone with on-off control.

- 1 Micro-port & 1 Membrane type Keofitt make sample valves with – shrouds.

- The tank is having cooling jackets on a shell and on the cone portion. The temperature of the tank is indicated by temperature transmitters located at the shell.

- Actuated on /off control valves are fitted for a tank to control the temperature of the tank. These valves will open or close to achieve a set temperature in a profile/auto mode. Manual on/off facility is also provided which can be operated from the screen.

- Temp setting can be done & adjusted as per requirement in HMI for heating and cooling applications during steam heating /Glycol cooling.

- Pressure transmitters are provided at the top & bottom which will note as differential pressure.

- These values will be automatically converted into volumes using level -volume program provided in the system. This will show accurate reading volume inside the vessel

- Level switch high/low is provided to avoided empty level & overfilling of system

Yeast Storage Section

Propagated yeast is stored in yeast storage tanks for several days. Temp and aeration should be maintained. The cooling jackets are provided at the shell to chill yeast up to 8-degree c. it also has aerator assembly for continuous supply for oxygen, frequent recirculation is done for homogenization.

- Cylindroconical tanks are complete with Shell, top dish, and bottom cone.

- Cooling jacket embossed type on cone & shell portion.

- Cone jackets & shell jackets are for glycol cooling.

- 1 Micro-port & 1 Membrane type Keofitt make sample valves with – shrouds.

- The tank is having cooling jackets on a shell and on a cone portion.

- Temperature of the tank is indicated by Temperature transmitters located at shell

- Actuated On /off Control valve are fitted for tank to control temperature of tank.

- These valves will open or close to achieve set temperature in profile / Auto mode.

- Manual On/Off facility is also provided which can be operated from screen.

- Temp setting can be done & adjusted as per requirement in HMI for heating and cooling applications during steam heating /Glycol cooling.

- Pressure transmitters are provided at top which will note pressure.

Yeast Pitching Section

Yeast pitching means an addition of the yeast to the wort and thus starting fermentation. The yeast addition is 15 to 30 million yeast cells/hl of wort. The pitching rate has a large effect on the fermenting time and yeast crop. The higher the pitching rate, the shorter the fermentation time at the same temp and more yeast can be harvested.

From the yeast storage tanks, yeast is pitched in the cool and aerated wort. Yeast pitching is done with the help of a lobe pump by connecting the pump suction line to the yeast storage tank outlet and discharge line to the wort line. The amount of yeast to be dosed controlled by a turbidity measuring system. Or it can be measured by lode cells/ flow meters at the storage tank.

- Load cells are provided to the tank to know Yeast Tank weight & the same will be used to pitch yeast quantity. This will show accurate reading of yeast inside the vessel.

- Level switch High/Low is provided to avoided empty level & overfilling of system.

- Yeast circulation /Cum pitching is provided to the yeast tanks tom pitch the yeast in wort line using an automated cycle defined in a program. ensure all swing bends are properly connected.

- Yeast is collected from unitank through yeast cropping pump & stored in yeast storage Tank.

- CIP return pump will work based on cycle selections defined into the program during the CIP of tanks.

We would love to see you on social media!

Utmost consideration of hygienic design

Yeast Propagation Plant & Yeast Storage Vessel are built using SS 304 L material and the surface is finished to < 0.6 uRa on our automatic polishing machines. The tank is equipped with CIP’able safety fittings; adequate instrumentation level for consistent output coupled to PLC-based automation. The design and construction of the vessel and associated pipework ensures contamination cannot occur. CIP supply pipe from an operating level in the cellar to the tank top routed through the insulation. A ladder is provided for accessibility to the tank top fittings. Hygienic Process piping, fittings butterfly valves where ever required in OD based in SS 304 material for Wort, Yeast, CO2 & Air vent, CIP S/CIP R.