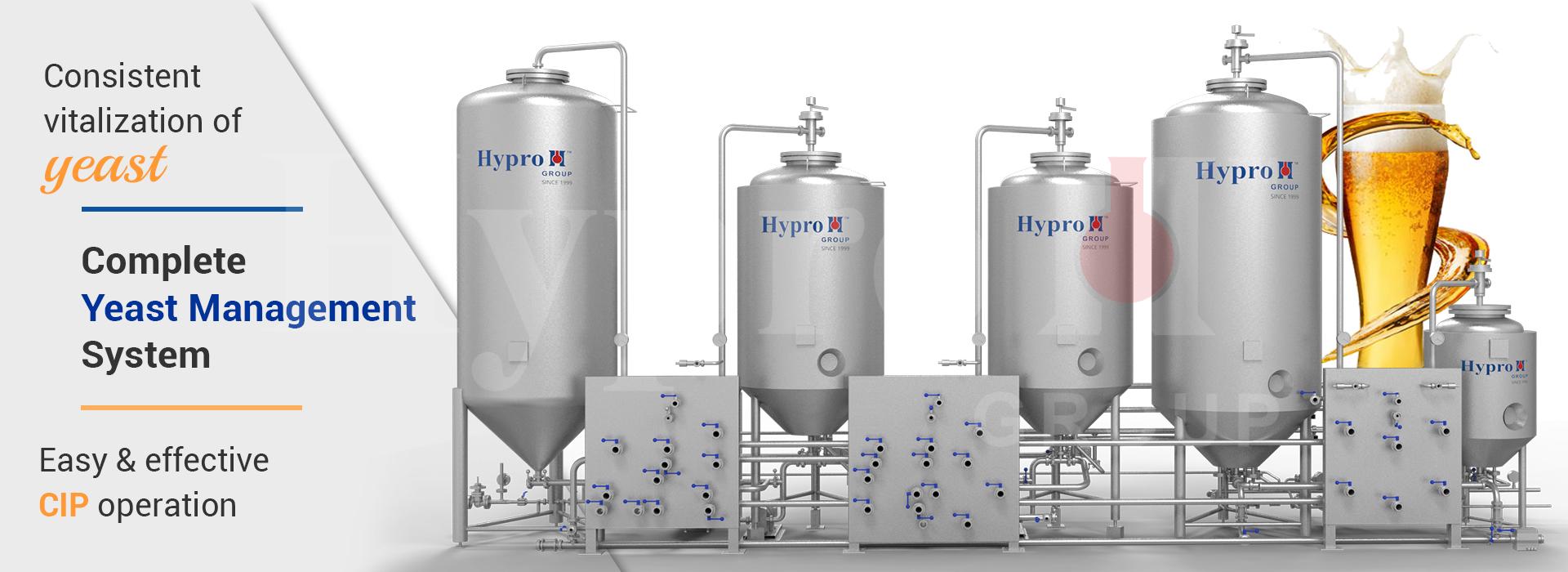

Uhlelo Lokuphatha Imvubelo

yakhelwe ngezici zenhlanzeko njengokugxilwa kwayo

Hypro Isixazululo esiphelele se-Yeast Management okubala I-Yeast Propagation, Storage & Pitching Systems aklanywe ngezici zenhlanzeko njengokugxilwa kwawo futhi anikeze i-Brewer isitshalo kanye nezisekeli zayo ezingaba yi-CIP ngempumelelo futhi zigcine ukungcola kude. I Imvubelo Storage Systems afakwe ukuyaluza ngesivinini esiphansi ukugwema ukulimala kwe-shear kumaseli we-yeast. I-Gravimetric pitching inikezwa njengendlela evamile.

Isigaba Sokusakazwa Kwemvubelo

I-yeast propagator inejakhethi yesitimu kugobolondo nejakhethi ye-glycol ku-cone.it futhi inembobo yokungenisa umoya eyodwa yokuhlinzeka komoyampilo okuqhubekayo. Ukufakwa kwethangi phezulu kwe-propagator kuhlanganisa iveluvu eyodwa ye-vacuum ekwaziyo i-CIP kanye ne-valve yokuphepha yokucindezela eyodwa ukuze kuphephe ithangi. Idivayisi ye-bunging nayo ifakwe kulayini we-CIP we-propagator.

Ngezizathu ezilandelayo ukusabalalisa imvubelo amasiko kudingekile

- Imvubelo ithatha futhi isakaze ukutheleleka ku-wort

- Uhlamvu lwemvubelo luyashintsha ngenxa yokuguqulwa kofuzo

- Ukuncipha kokusebenza kanye nobungqabavu be-yeast ngokuhamba kwesikhathi nokuphinda kufakwe.

- Amaseli afile anikela ngama-protease namanothi e-flavour angafuneki kubhiya.

- Ukuguga kwemvubelo kubangela ukwehla kwezinga lokuzala.

- Ukuguga kwemvubelo kubangela izinguquko ebusweni beseli kanye nokuziphatha kwe-flocculation.

- Ukuguga kwemvubelo kubangela ushintsho ekuziphatheni kwe-metabolic.

- Ukuguga kweyeast kubangela ukwanda okuvamile kosayizi weseli

Inani elincane okungukuthi i-1gm yemvubelo ixutshwe ne-wort ene-gravity evamile.ie 16-14-degree Plato, bese kuba igcinwe eflaskini izinsuku eziyisi-6 kuya kweziyisi-7 lapho kukhona umoya-mpilo. I-aeration iyinqubo eqhubekayo. Izinga lokushisa kufanele ligcinwe ku-18-20-degree C. Khona-ke ukumiswa kweyeast eflaskini ye-Carlsberg kugcwaliswa ku-propagator futhi kancane kancane kuhlanganiswe ne-wort entsha ngenkathi ifakwe umoya futhi i-homogenized - kuze kube yilapho kutholakala inani lemvubelo elifiswayo kanye nokugxiliswa kweseli eliceliwe.

I-Yeast Propagator noma i-a isigaba esisodwa noma izigaba ezimbili. I-Yeast Propagator yokupholisa kanye nesistimu yokushisisa iklanyelwe ubuningi bewort echazwe ngaphambilini ngaleyo ndlela yenza kube lula ukuvalwa kwe-wort kanye nokupholisa kwayo ngokushesha. Ukuze kusakazeke imvubelo, i-propagator ifakwe emoyeni oyinyumba ngendlela yokuphefumula ngaphakathi komkhumbi noma ngaphandle ngesikhathi sokujikeleza. I-Internal Air sparger iwuhlobo olukhipheka kalula olune-CIP/SIP. Ukusheshisa nokukhuthaza ukusabalalisa i-wort isakazwa ngaphakathi komkhumbi.

Imvubelo isakazwa ukuze I-7 ezinsukwini ezingu-8 ngesikhathi temp 18-20-degree c. ukuze kuqinisekiswe ukusabalala imvubelo ngokuphelele amandla adonsela phansi imvubelo ihlolwe njalo. Lapho imvubelo amandla adonsela phansi kufika evamile 16-14-degree U-Plato wabe esedluliselwa ethangini lokugcina imvubelo. Ukuze kudluliswe imvubelo, kusetshenziswa iphampu ye-lobe. Le futha ngokuvamile ihlinzekwa ngesilawuli sefrikhwensi eguquguqukayo.

- Amathangi e-Cylindroconical aphelele nge-Shell, isitsha esiphezulu, nekhoni engezansi.

- Uhlobo lwejakhethi yokushisisa nelokupholisa kukhoni nengxenye yegobolondo.

- Amajakhethi e-cone awokushisisa isitimu namajakhethi egobolondo awokupholisa i-glycol

- Ingxenye eyodwa yokupholisa kugobolondo enokulawula okucishayo kanye nendawo yokushisisa Eyodwa kukhoni engezansi ene-On/Off control

- Izigaba ezimbili zokupholisa kugobolondo nekhoni enokulawula okucishiwe.

- 1 Imbobo encane kanye nohlobo lweMembrane engu-1 i-Keofitt yenza ama-valve esampula – ngamashidi.

- Ithangi linamajakhethi okupholisa egobolondweni nasengxenyeni yekhoni. Izinga lokushisa lethangi liboniswa ama-transmitter okushisa atholakala kugobolondo.

- Amavalvu okulawula avuliwe/avaliwe afakwa ithangi ukulawula izinga lokushisa ethangini. Lawa mavalvu azovuleka noma avale ukuze kufinyelele izinga lokushisa elimisiwe kuphrofayela/imodi ezenzakalelayo. Isikhungo sokuvula/ukuvala sinikezwa futhi esingasetshenzwa esikrinini.

- Ukulungiselelwa kwesikhashana kungenziwa futhi kulungiswe ngokwesidingo se-HMI sokushisisa nokupholisa izinhlelo zokusebenza ngesikhathi sokushisisa isitimu / ukupholisa kweGlycol.

- Ama-pressure transmitters anikezwa phezulu naphansi okuzobonakala njengokucindezela okuhlukile.

- Lawa manani azoguqulwa ngokuzenzakalela abe amavolumu kusetshenziswa uhlelo lweleveli -volume olunikezwe ohlelweni. Lokhu kuzobonisa ivolumu yokufunda enembile ngaphakathi komkhumbi

- Ukushintshwa kwezinga eliphezulu/phansi kunikezwa ukuze kugwenywe izinga elingenalutho kanye nokugcwaliswa ngokweqile kwesistimu

Isigaba Sokugcina Imvubelo

Imvubelo esakazwayo igcinwa emathangeni okugcina imvubelo izinsuku ezimbalwa. Izinga lokushisa nomoya kufanele kugcinwe. Amajakhethi okupholisa ahlinzekwa egobolondweni ukuze kuphole imvubelo kufika ku-8-degree c. iphinde ibe nomhlangano we-aerator wokuhlinzeka ngokuqhubekayo kwe-oxygen, ukuphindaphinda njalo kwenziwa ukuze kuhlanganiswe i-homogenization.

- Amathangi e-Cylindroconical aphelele nge-Shell, isitsha esiphezulu, nekhoni engezansi.

- Ijakhethi yokupholisa uhlobo oluqoshwe kukhoni & ingxenye yegobolondo.

- Amajakhethi ekhoni namabhantshi egobolondo awokupholisa i-glycol.

- 1 Imbobo encane kanye nohlobo lweMembrane engu-1 i-Keofitt yenza ama-valve esampula – ngamashidi.

- Ithangi linamajakhethi okupholisa egobolondweni nasengxenyeni yekhoni.

- Izinga lokushisa lethangi liboniswa ngama-Temperature transmitters atholakala kugobolondo

- Ivalvu yokulawula evuliwe/evaliwe ifakelwe ithangi ukulawula izinga lokushisa lethangi.

- Lawa ma-valve azovula noma avale ukuze kuzuzwe izinga lokushisa elimisiwe kuphrofayela / Imodi ye-Auto.

- I-Manual On/Off indawo nayo ihlinzekiwe engasetshenziswa esikrinini.

- Ukulungiselelwa kwesikhashana kungenziwa futhi kulungiswe ngokwesidingo se-HMI sokushisisa nokupholisa izinhlelo zokusebenza ngesikhathi sokushisisa isitimu / ukupholisa kweGlycol.

- Ama-pressure transmitters anikezwa phezulu azophawula ingcindezi.

I-Yeast Pitching Section

Ukufaka imvubelo kusho ukwengeza imvubelo ku-wort futhi ngaleyo ndlela kuqale ukuvutshelwa. Ukwengeza imvubelo yi-yeast cells/hl ye-wort eyizigidi ezingu-15 kuya kwezingu-30. Izinga le-pitching linomthelela omkhulu esikhathini sokuvubela kanye nesivuno semvubelo. Uma izinga lokuvubela liphakeme, isikhathi sokuvutshelwa siba sifushane ngesikhathi esifanayo futhi imvubelo eyengeziwe ingavunwa.

Kusuka emathangeni okugcina imvubelo, imvubelo ifakwa ku-wort epholile futhi ene-aerated. I-yeast pitching yenziwa ngosizo lwepompo ye-lobe ngokuxhuma umugqa wokudonsa wepompo endaweni yokukhipha ithangi lokugcina imvubelo kanye nomugqa wokukhipha emgqeni we-wort. Inani lemvubelo elizofakwa umthamo lilawulwa isistimu yokulinganisa i-turbidity. Noma ingakalwa ngama-lode cells/flow meters ethangini lokugcina.

- Amaseli omthwalo anikezwa ethangini ukuze azi isisindo se-Yeast Tank futhi okufanayo kuzosetshenziselwa ukumisa ubuningi be-yeast. Lokhu kuzobonisa ukufundwa okunembile kwemvubelo ngaphakathi komkhumbi.

- Ukushintsha ileveli Okuphezulu/Phansi kunikezwa ukuze kugwenywe izinga elingenalutho nokugcwaliswa ngokweqile kohlelo.

- Ukujikeleza kweyeast / I-Cum pitching inikezwa ku-yeast tanks tom pitch the yeast in wort line usebenzisa umjikelezo ozenzakalelayo ochazwe ohlelweni. qinisekisa ukuthi wonke ama-swing bend axhumeke kahle.

- I-yeast iqoqwa ku-unitank ngokusebenzisa iphampu yokunqampuna imvubelo futhi igcinwe ethangini lokugcina imvubelo.

- Iphampu yokubuyisela ye-CIP izosebenza ngokusekelwe ekukhethweni komjikelezo okuchazwe ohlelweni ngesikhathi se-CIP yamathangi.

Singathanda ukukubona ezinkundleni zokuxhumana!

Ukucatshangelwa okukhulu komklamo wokuhlanzeka

Isitsha Sokusabalalisa Imvubelo kanye Nomkhumbi Wesitoreji Semvubelo zakhiwe kusetshenziswa I-SS 304 L impahla kanye nengaphezulu kuqediwe ku-<0.6 uRa emishinini yethu yokupholisha okuzenzakalelayo. Ithangi lifakwe izinto zokuphepha ze-CIP'able; izinga lensimbi elanele lokukhiphayo okungaguquki kuhlanganiswe I-PLC-based automation. Ukuklanywa nokwakhiwa komkhumbi kanye namapayipi ahambisanayo kuqinisekisa ukuthi ukungcoliswa ngeke kwenzeke. Ipayipi lokunikezela nge-CIP ukusuka ezingeni lokusebenza endaweni engaphansi kuya phezulu kwethangi elihanjiswa ngokufakwa ngaphakathi. Isitebhisi sinikezwa ukuze kufinyeleleke okufakwayo phezulu kwethangi. Amapayipi enqubo yokuhlanzeka, amavalvu ovemvane okufakwayo lapho edingeka khona ku-OD asuselwa ku-SS 304 impahla ye-Wort, Yeast, CO2 Nokungenisa umoya, i-CIP S/CIP R.