Industrial Unitanks

tag nrho customized daws teeb meem

Hypro tsim thiab tsim txog li 5000HL Unitanks / Fermentation Tanks nyob rau hauv ib thooj hauv lub hoobkas. Peb kuj muab kev daws teeb meem rau ntawm qhov chaw uas kev thauj mus los yog qhov txwv. Hauv qhov xwm txheej zoo li no, cov khoom siv tank tau sib sau ua ke ntawm qhov chaw. Prefabricated surfaced tiav sab saum toj phaj kawg, hauv qab lub khob hliav qab, cov khoom siv plhaub raug xa mus rau qhov chaw. Txuas ntxiv 5 xyoo cov chaw tsim khoom lav hais txog kev ntseeg siab thiab kev thaj yeeb ntawm lub siab rau peb cov neeg siv khoom. Hypro muaj ib pab neeg tsim nyog thiab muaj kev paub dhau los los daws cov haujlwm ntawm qhov xwm txheej no. Cov automation system yog zoo xav thiab xaiv txoj cai los ntawm sensors, controllers, thiab zaum kawg tswj ntsiab.

Raws li lub npe qhia Unitanks yog siv nyob rau hauv ib tug brewery rau peb-unit ua hauj lwm / txheej txheem ua nyob rau hauv ib tug tank. Cov txheej txheem ua haujlwm / txheej txheem yog:

- Fermentation ntawm wort los tsim ntsuab npias.

- Txias ntawm ntsuab npias los ntawm fermentation kub mus rau maturation kub.

- Maturation ntawm npias los tsim cov hluas npias

Aerated Cold wort los ntawm brewhouse pitched nrog fermenting poov xab yog sau rau hauv Unitanks batch-wise. (Nquag 2-6 brews / tank). Raws li fermentation ntawm cov extract pib, nws tsim cawv thiab CO2. Txij li thaum cov tshuaj tiv thaiv yog exothermic nyob rau hauv cov xwm, tshav kub yog hloov zuj zus mus thiab yog dissipated los ntawm circulating glycol nyob rau hauv lub txias tsho ntawm lub Unitank. Qhov kub thiab txias tau txais kev tswj hwm hauv Unitank los ntawm PC-PLC raws li qhov system. Lub logic tswj tau raug txhais nyob rau hauv cov ntaub ntawv tswj logic. Thaum kawg ntawm lub voj voog fermentation, thawj lub voj voog txias pib. Hauv thawj theem ntawm kev ua kom txias, npias yog txias los ntawm fermentation kub mus rau 4 Deg C. Ntawm qhov kub no, cov poov xab nyob rau hauv qab yog sau los ntawm Unitank thiab pumped mus rau Poov cog. Tom qab tshem tawm cov poov xab, theem thib ob ntawm lub voj voog txias pib qhov twg npias txias mus rau -10C. Tom qab ua tiav qhov kub ntawm -1 Deg C Maturation voj voog pib thiab npias yog matured nyob rau hauv Unitanks rau ib lub sij hawm ntawm 5-7 hnub. CO2 counter-pressure yog siv thaum lub sij hawm lub voj voog no los tswj cov CO2 huab cua hauv npias thiab zam kom tsis txhob muaj oxygen.

- Peev xwm los ntawm 50L txog 5000 HL

- Tsim raws li ib ASME Sec VIII Div 1 & cov qauv kev tu cev zaum kawg

- Raw khoom SS304L - European mills

- Ua kom tiav cellar systems nrog ntws daim hlau

- Cov nqi cua txias - haum rau lub voj voog txias 24-48 teev

- Glycol ncig lub tsho tsim los rau qhov zoo glycol ncig thiab qis qis qis

- Tshuab av nto 0.8-0.4Ra

- TTP-kev nyab xeeb fittings & tank tu m / c imported los ntawm cov teb chaws Europe

- Cellar Process & Utility Piping meeting cov qauv kev tu cev ua haujlwm thiab CIP yooj yim dua rau cov brewery ntau xyoo

- Platforms & Walkways uas tuaj yeem yooj yim bolted ntawm qhov chaw thiab tsis muaj vuam yog tsim nyog rau kev sib dhos

- Tank nrog welded cladding rau hauv qab lub khob hliav qab thiab lub tais saum toj kawg nkaus uas ua haujlwm rau lub neej ntev ntawm rwb thaiv tsev thiab zoo nkauj zoo nkauj

- Manholes thiab Sab saum toj Phaj rau kev tuav tau yooj yim thaum lub sijhawm tsim khoom, kuj ua kom yooj yim ntawm kev tu kom muaj qhov zoo ntawm lub xyoo tom qab xyoo.

- PLC-SCADA raws li automation txhawb nqa cov ntaub ntawv kaw lus, keeb kwm, kev tswj daim ntawv qhia, thiab tiam sis

- FERMAT - Cov Ntaub Ntawv Tswj Xyuas Software, tso cai rau koj los sib piv cov qauv thiab qhov tsis sib xws ntawm ntau yam fermentation batches

- Sab nraum zoov Installation

- Txo tus neeg teb xov tooj kev cia siab

- Tank tu tshuab rau kev siv dej tsawg thiab high efficiency ntawm tu

- Wort nyob rau hauv: Txuas lub wort mains kab mus rau Unitank hauv qab siv Swing Khoov. Lub valve ntawm CIP - GAS kab yuav tsum qhib kom tso pa tawm thaum lub sij hawm sau wort hauv Unitank. Chasing/Switching over from products to water or vice versa is done using a diverter valve with pom iav arrangement as displayed in the P&I Diagram.

- CO2 Sau: Txuas GAS kab mus rau CO2 sau header los ntawm kev siv lub viav vias khoov thiab qhib li qub ntawm cov kab. Feem ntau ua tom qab ua tiav purity ntawm 99.7% v / v ntawm CO2 gas los ntawm Unitank. Feem ntau tom qab 36 teev txij li thaum pib fermentation.

- Yeast Draw: Txuas cov poov xab mains kab mus rau Unitank hauv qab siv lub viav vias Khoov. Lub valve ntawm CIP -GAS kab yuav tsum qhib kom tso cai rau cov pa nkag mus rau Unitank kom tswj tau cov pa zoo. Chasing/Switching over from products to water or vice versa is done using a diverter valve with pom iav arrangement as displayed in the P&I Diagram.

- Beer tawm: Txuas lub npias mains kab mus rau Unitank hauv qab siv lub viav vias Khoov. Lub valve ntawm CIP -GAS kab yuav tsum tau qhib kom tso pa roj nkag mus rau Unitank kom tswj tau cov pa zoo rau cov pa roj CO.2 cov kab xa khoom yog muab uas tuaj yeem txuas nrog viav vias khoov mus rau Unitank Gas inlet kab. Chasing / Hloov ntawm cov khoom mus rau dej los yog vice versa yog ua tiav siv lub diverter valve.

- CIP ntawm Unitank: Tom qab txhua batch, CIP ua tiav hauv Unitank. Xyuas kom meej tias thaum lub sij hawm CIP lub voj voog cov kua yog pumped ntawm lub siab txaus. (5.0 Bar ntawm qhov ntsuas siab ntawm CIP Kab nrog 15-17 m3 / hr ntws). Muaj ib qho kev qhia rau CIP ntawm Anti vacuum Valve nyob rau saum phaj. Lub Valve no tau muab nrog kev tiv thaiv txaws los tiv thaiv kev sib tsoo ntawm lub phaj sab saum toj.

- Kub CIP ntawm cov txheej txheem kab: Nws cov qauv kev coj ua los ua cov kab CIP ntawm tag nrho cov txheej txheem headers (Wort, Poov, CIP R). Tag nrho cov txheej txheem headers raug ntxuav & chased siv HOT CIP & txheem CIP cycles uas yuav tsum tau flowrates & siab ntawm 3-4 tuav.

- CO2 Khoom siv: Ib qho kev npaj tau ua los muab CO2 mus rau Unitank. The CO2 Cov kab xa khoom tuaj yeem txuas nrog Unitank los ntawm kev siv lub viav vias khoov.

- Cylindroconical Unitanks ua tiav nrog Plhaub, tais sab saum toj, thiab hauv qab lub khob hliav qab.

- Lub tsho txias txias embossed / dimpled hom ntawm lub plhaub feem thiab cov nplaim paj / embossed hom ntawm lub khob hliav qab.

- Thermo-wells nrog shrouds ntawm Plhaub thiab On Cone.

- Qhov chaw txias txias (raws li qhov tsim) yog nyob rau ntawm lub plhaub thiab nyob rau hauv qab lub khob hliav qab.

- Qauv valve: Membrane yam Keofitt ua nrog keyrings - shrouds, ntws rau shrouds.

- CIP muab cov yeeb nkab los ntawm qib kev khiav hauj lwm hauv cellar mus rau lub tank saum toj kawg nkaus tau dhau los ntawm kev rwb thaiv tsev.

- Dome ntws yeeb nkab khiav los ntawm lub tank sab saum toj mus rau sab saum toj ntawm slab routed hauv lub insulating.

- Cable conduit kav xa mus rau hauv lub rwb thaiv tsev.

- Glycol muab thiab xa rov qab cov kav dej los ntawm lub tank mus rau Supply headers hauv SS 304 & xa mus rau hauv lub rwb thaiv tsev. Glycol muab thiab xa rov qab cov kav dej los ntawm cov headers tseem ceeb los muab cov headers hauv

- SS304 nrog PUF rwb thaiv tsev & SS304 cladding.

- Lifting lugs nrog detachable npaj rau nruab platform ntawm qhov chaw.

- Skirt nrog ceg txhawb nqa hauv MS kub-dip galvanized.

- Platform hauv kub sib sib zog nqus galvanized khoom rau Unitank ua tiav nrog railings.

- Hygienic txheej txheem piping, fittings npauj npaim li qub nyob qhov twg yuav tsum tau nyob rau hauv

- OD raws li SS 304 cov khoom siv rau Wort, Npias, Poov xab, CO2 & Cua vent, CIP S/CIP R.

- Lub tank muaj cov tsho txias rau ntawm lub plhaub thiab lub khob hliav qab.

- Qhov kub ntawm lub tank yog qhia los ntawm qhov kub thiab txias transmitters nyob rau sab saum toj ntawm lub plhaub thiab nyob rau sab saum toj ntawm lub khob hliav qab.

- Actuated npauj npaim li qub yog haum rau lub tank los tswj qhov kub ntawm lub tank.

- Cov li qub no yuav qhib lossis kaw kom ua tiav qhov ntsuas kub hauv qhov profile / pib hom.

- Los ntawm txhais tes rau / tawm qhov chaw tseem muaj uas tuaj yeem ua haujlwm ntawm qhov screen.

- Cov kab ke no yog ua tiav tag nrho & ua haujlwm los ntawm SCADA nrog cov txheej txheem tswj kev tswj xyuas.

- CIP Return Pump yog trolley mounted & yuav pib / nres raws li cov kauj ruam ntawm CIP lub voj voog kev pab cuam txhais rau cellar CIP & kab CIP ntawm cov khoom siv.

- Powder cropping twj tso kua mis kuj trolley mounted & automated ua los ntawm SCADA

- Cov poov xab sau los ntawm Unitank & hloov mus rau cov poov xab thiab lwm yam kev ua haujlwm yog los ntawm kev xaiv lub voj voog los ntawm SCADA

Peb xav pom koj hauv social media!

Feem ntau zoo tagnrho fermentation tej yam kev mob

nrog automaton

Manholes & Sab saum toj daim hlau

Hypro tau customized manhole tsim rau sab saum toj thiab hauv qab thiab ua txoj kev yooj yim tuav thaum lub sij hawm ntau lawm. Cov qauv tsim ua kom yooj yim ntawm kev tu kom tswj tau qhov chaw zoo txhua xyoo.

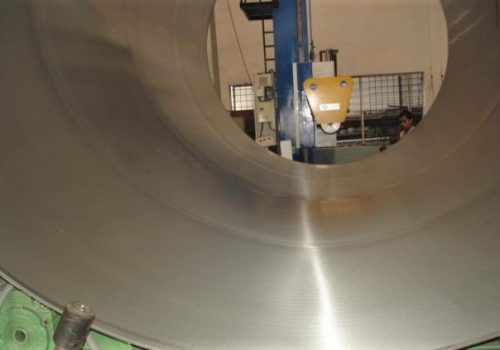

Internal Surface tiav

Qhov tseem ceeb tshaj plaws thaum lub sijhawm tsim khoom ntawm Unitanks. Kom paub meej qhov chaw tas mus li thoob plaws "Hypro"muaj cov tshuab polishing tsis siv neeg uas tuaj yeem tuav cov plhaub, tsim cov tais diav, conical xaus. Sab hauv thiab sab nrauv polishing tuaj yeem ua tiav nrog cov tshuab uas ua kom cov npoo du thiab zoo nkauj.

Cellar Process & Utility Piping

Cellar txheej txheem piping meets "Hygienic" cov qauv ua rau kev ua haujlwm ntau xyoo yooj yim rau cov brewery los ntawm kev ua haujlwm & CIP nam. Raws li tus qauv "Hypro"Siv cov khoom siv hlau tsis muaj steel rau cov kav dej ntawm kev siv hluav taws xob nyiam glycol lossis dej cawv.

Platforms / Taug kev

Platforms tuaj nyob rau hauv cov khoom uas tuaj yeem yooj yim bolted ntawm qhov chaw thiab tsis muaj vuam yog tsim nyog rau kev sib dhos. Raws li kev xaiv "Hypro" kuj tseem muaj cov platforms hauv Stainless Steel cov khoom uas yuav luag tshem tawm cov hlau me me lossis cov khoom siv hlau galvanized.

Tank Sab saum toj Fittings

Tank saum tuaj nrog cov khoom siv kev nyab xeeb txhim khu kev qha los ntawm cov neeg muag khoom nyob sab Europe. Kev tu lub tank raws li tus qauv "Hypro" pom zoo kom ntxuav lub tank uas hnyav rau thawj peev tab sis lawv them rov qab nrog cov dej txuag hauv lub sijhawm.

Caug

Raws li tus qauv "Hypro" ib txwm tsim cov tso tsheb hlau luam nrog welded cladding rau hauv qab lub khob hliav qab thiab sab saum toj tais uas thaum kawg ua haujlwm rau lub neej ntev ntawm rwb thaiv tsev thiab zoo nkauj zoo nkauj.

Cov Lus Nquag Nug.

Qhov no yog ib qho yooj yim txheej txheem. Tsis txhob siv cov kua qaub ua ntej. Txhawm rau tshem tawm cov tshuaj los yog vuam lubricants los ntawm koj lub tank tshiab, koj yuav tsum xub khiav lub voj voog tu nrog cov tshuaj caustic. Peb pom zoo kom khiav ob lub voj voog sib cais kom huv si. Tsis txhob siv cov kua qaub ua ntej, vim tias cov seem dawb yuav tsim. Koj yuav tsum ib txwm ntxuav koj lub tank tom qab tau txais los ntawm lub Hoobkas.

Lub Unitanks tsis muaj lub pob tsuag nrog. Lub Unitanks tuaj nruab nrog 3 "TC Accessory chaw nres nkoj uas koj tuaj yeem tso 3" Spray Ball.

Tsis yog, Unitanks tsis muaj cov cim ntim sab hauv.

Txawm hais tias Unitank muaj peev xwm ua haujlwm rau npias ncaj qha, nws raug nquahu kom koj hloov lub npias mus rau lub nkoj ua haujlwm siab zoo xws li Brite Beer Tank lossis Keg kom tsis txhob muaj kev sib kis tsis zoo ntawm fermentation by-product nyob rau hauv cov brew tiav.

Peb sim tag nrho peb cov tso tsheb hlau luam rau qhov zoo tshaj plaws ua ntej muab peb 5-xyoo warranty rau lawv. Qhov no suav nrog txhua yam teeb meem nrog lub tank ua haujlwm uas yuav suav tias yog lub Hoobkas yuam kev. Peb kuj hloov qhov tawg lossis qhov tsis zoo yuav tsum tshwm sim hauv 5 xyoo warranty lub sijhawm. Peb xav tau cov duab ntawm qhov puas lawm ua ntej pab nrog warranty muaj feem cuam tshuam. Yog tias peb txiav txim siab tias nws yog tus neeg ua haujlwm yuam kev peb yuav tsis them rau kev hloov lossis kho. Lub warranty yuav tsis muaj tseeb yog tias koj ua ib qho kev hloov pauv lossis kev tsim khoom rau lub tank tom qab kev yuav khoom. Peb tsis lav lwm tus neeg txoj haujlwm ua haujlwm.

Feem ntau ua ke nrog

Hypro Fermentation Tso Tsheb Hlau Luam muab cov xwm txheej zoo li no. Lawv raug kho kom haum rau ntau hom thiab cov txheej txheem tshwj xeeb ntawm fermentation parameter tswj ua los ntawm koj lub brewery. Peb cov hlab ntsha yog tsim los nrog ntau yam, tso cai rau tag nrho cov kev ua haujlwm brewery ua ke hauv cov nkoj tsawg dua rau kev lag luam, lossis muab cais ua ntau lub nkoj kom muaj peev xwm ntxiv.