#Beer #CO2 #Brewery #CarbonNeutral

CO2 Recovery Myths Debunked by Hypro for Small-Scale Brewing Operations

There is a looming worldwide shortage of CO2, caused by different circumstances, creating a crisis across all industries. The brewing industry has been particularly hard hit, facing hiked prices, supply problems, and even rationing. In the realm of small-scale brewing, the notion that CO2 recovery is unattainable has long persisted as a stubborn myth. However, Hypro is leading a revolution in CO2 recovery, shattering these misconceptions with innovative solutions tailored specifically for smaller players in the industry.

Myth #1: CO2 recovery systems take up too much space for small breweries.

Reality: Space constraints are a common concern for small-scale breweries, leading to the belief that CO2 recovery systems are impractical due to their size. However, Hypro’s compact and modular designs address this issue effectively.

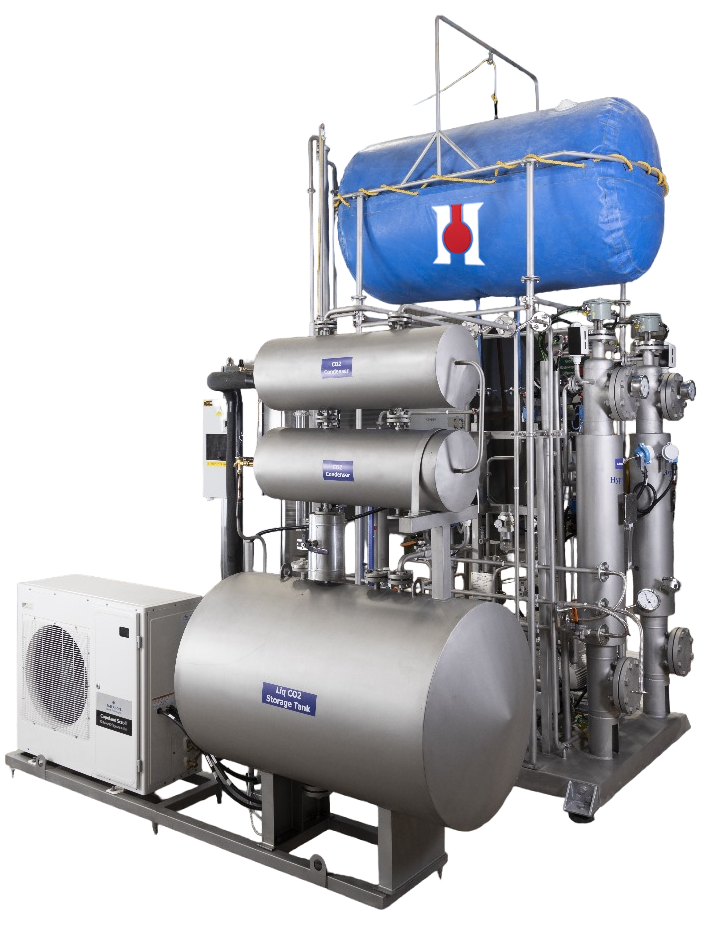

Our CO2 recovery system namely HyCrCTM are specifically engineered to fit into small footprints, making them ideal for breweries with limited space. The modular design allows for flexible installation, enabling brewers to optimize their available area without sacrificing functionality or efficiency.

Furthermore, the integration of digital monitoring and control systems means that physical oversight requirements are minimized, further reducing the space needed for operational purposes. This innovative approach ensures that even the smallest breweries can benefit from CO2 recovery without compromising their workspace.

By offering space-efficient solutions, Hypro dispels the myth that CO2 recovery is only for larger operations, proving that sustainability and efficiency are achievable for breweries of all sizes.

Myth #2: CO2 recovery systems for craft breweries can't match the quality and efficiency of those used in large industrial breweries.

Reality: Many believe that CO2 recovery systems designed for craft breweries are inherently inferior to those used in large industrial operations. However, Hypro’s technology dispels this myth by offering a scaled-down version of the advanced systems employed by global brewers, ensuring the same high level of performance and quality.

Hypro’s CO2 recovery plants for craft breweries produce CO2 with a purity of 99.998%, equivalent to the industrial-grade systems, and significantly higher than the 99.99% purity achieved by other solutions. This ensures that craft breweries can rely on the same superior quality CO2 as their larger counterparts.

Additionally, Hypro’s technology minimizes back pressure on fermenters, unlike other systems that can impose pressures of 0.3 to 0.4 bar. This feature ensures that Hypro’s systems operate efficiently without compromising the brewing process. The flexibility of Hypro’s plant operations allows for seamless adaptation to varying CO2 generation rates, from as low as 2 kg per hour to higher capacities, making it ideal for craft breweries of all sizes.

Furthermore, Hypro’s innovative systems can recover CO2 from counter-pressure operations, including from BBTs and Unitanks, ensuring no CO2 goes to waste. The inclusion of an inbuilt distillation column guarantees the highest purity levels, distinguishing Hypro from other solutions that lack this capability.

Myth #3: CO2 recovery plants demand high maintenance.

Reality: Hypro’s cutting-edge CO2 recovery plants are engineered to require minimal maintenance, debunking the myth that these systems are labor-intensive. Our collaboration with top global suppliers guarantees high-quality components, while efficient spares tracking and execution turn strategic inventory management into reality.

Key Features:

Long-Term Vision: Our 25-year forward-looking approach includes 360o control, HySAAA alarms, and both preventive and predictive maintenance, keeping your operations efficient and hassle-free.

Digitalized Operation and Maintenance (O&M): With digital tools and cloud-based solutions, breweries can access FAQs and troubleshooting guides, enabling operators to resolve many issues independently.

Exceptional After-Sales Support: We offer prompt, comprehensive support and services to keep your system running seamlessly.

Data Accessibility: Our skilled software team is available for guidance and coordination, enabling digitalized data at your fingertips. This allows you to effortlessly monitor and manage your plant, eliminating the need for traditional log sheets.

Operator Training: During commissioning, we provide thorough training for your operators, ensuring they are well-equipped to handle routine maintenance tasks. This includes a comprehensive maintenance checklist for ongoing system care.

Hypro’s advanced technology reduces dependency on external support, allowing breweries to maintain their CO2 recovery systems efficiently and independently. By dispelling this myth, we empower small-scale breweries to embrace sustainable practices with confidence.

Myth #4: Switching to nitrogen is a better alternative to CO2 recovery for small breweries.

Reality: Many small breweries consider switching to nitrogen due to rising CO2 costs, believing it to be a more cost-effective solution. However, the reality is that using nitrogen as a substitute for CO2 is both complex and capital intensive. Achieving the necessary high purity for nitrogen, with oxygen levels below 5 ppm, requires significant investment in technology and ongoing operational costs.

Hypro addresses this challenge with its innovative CO2 recovery solutions tailored for small breweries, offering systems that range from as small as 8 kg per hour to larger capacities. By understanding the diverse applications of CO2 in brewing, from carbonation to tank transfers and counter-pressure processes, Hypro maximizes CO2 recovery and efficiency.

Our Counter Pressure Recovery (CPR) technology enables breweries to reclaim CO2 used in various stages of the brewing process, significantly reducing overall consumption. With Hypro’s solutions, breweries can lower their CO2 usage from an average of 4.5-5.5 kg per HL to about 3-3.5 kg per HL, achieving up to 40% savings.

Myth #5: My brewery produces 30,000 HLPA; a CO2 recovery plant won’t be viable for us.

Reality: There’s a common belief that CO2 recovery systems are only suitable for very large breweries or that they aren’t economically feasible for medium-scale operations. However, Hypro’s HyCrCTM technology proves that even breweries producing as little as 20,000 HLPA can significantly benefit from CO2 recovery.

First, consider the economic viability. In many regions, the cost of CO2 can be quite high, especially in remote areas where transportation and handling add to the expense. By investing in a HyCrCTM plant, breweries can become self-sufficient, eliminating dependence on external CO2 sources. This ensures a steady, reliable supply of food-grade CO2 from a known, sustainable origin.

In some countries, the cost of purchasing CO2 is so high that breweries can achieve a break-even point within 1.5 to 2 years of investing in a HyCrCTM plant. This rapid return on investment highlights the financial advantages of CO2 recovery, even for medium-sized breweries.

From an environmental perspective, capturing CO2 at its source rather than letting it escape into the atmosphere is highly beneficial. This practice not only reduces the brewery’s carbon footprint but also aligns with global sustainability goals. Many governments offer subsidies and incentives for installing CO2 recovery systems, further enhancing the economic appeal.

By debunking this myth, Hypro demonstrates that CO2 recovery is not only viable but also a smart economic and environmental choice for breweries producing 20,000 HLPA or more. Investing in a HyCrCTM plant can provide significant cost savings, ensure a reliable CO2 supply, and contribute positively to the environment, making it a wise choice for a wide range of breweries.

In essence, Hypro's technology proves that craft breweries can achieve the same quality, efficiency, and operational benefits as large industrial breweries, debunking the myth that CO2 recovery systems for smaller operations are inherently inferior. Hypro’s advanced, space-efficient, and low-maintenance CO2 recovery plants - HyCrCTM offer a sustainable, cost-effective alternative to traditional methods.

Join the revolution in brewing sustainability. Embrace Hypro’s cutting-edge CO2 recovery technology and take a confident step towards a greener, more efficient future. Contact us today to learn more about how Hypro can transform your brewery’s operations and sustainability efforts.

Related Posts

Hops Processing

Explore the latest trends in hops processing, including sustainability, specialty hops, advanced technologies, and global market opportunities.

Read MoreTurnkey Industrial Brewery

From bare land to brewing legacy — setting up an industrial brewery is more than installation. Hypro’s turnkey approach blends deep engineering with brewmaster intuition....

Read MoreBeer and Wine Sustainability Showdown: Tracing the Footprint from Soil to System

Every glass begins with the earth beneath it. Beer and wine sustainability isn’t brewed or fermented—it’s grown. This piece journeys from soil to system, uncovering...

Read More