#environment #CO2 #sustainability #circulareconomy

Environment first: A resilient circular carbon journey led by Hypro

The environment isn’t a backdrop.

It’s the breath between our words, the space between our machines, the very rhythm of existence. On this World Environment Day, the question isn’t whether we understand the damage – it’s whether we dare to become the cure.

For decades, progress was measured in lines – growth curves, production graphs, expansion plans. And in chasing those lines, we often forgot the circles: the closed loops that nature always honored. The sun rises, rains fall, forests breathe out what we breathe in. But industry, for far too long, exhaled without listening.

Now, we stand at a crossroads. One path leads to further depletion – familiar, paved, and perilously easy. The other bends toward restoration. Not a return to some untouched past, but a deliberate redesign of our systems, our values, and our outcomes.

In this new world, carbon is no longer the enemy. It’s the misunderstood twin of progress – wild when ignored, wise when guided. To capture CO₂ is not simply to trap a gas, but to acknowledge a truth: that we can’t extract endlessly from the planet without learning to give something back.

World Environment Day is not just a date on the calendar. It’s a mirror. And this year, as we face it, we ask ourselves – what does innovation mean if it doesn’t heal? What is growth, if it forgets the soil it stands on?

From Waste to Wealth: Circularity Rooted in the Environment

For centuries, our industries have moved in lines – forward, fast, and final. Extract. Produce. Discard. The system was simple, but blind. It left behind trails of carbon, forgotten effluents, and silenced ecosystems. Nature, however, has always spoken in circles. The fallen leaf becomes soil. The spent air becomes breath. Nothing is wasted – everything returns.

This is the quiet wisdom behind circularity – not just a method, but a mindset. And in the heart of that mindset is a commitment that Hypro has made its mission: to close the loops that industry once left open.

At Hypro, we don’t see carbon as a curse. We see it as a call – to innovate, to recover, to reimagine what progress can mean when it regenerates.

Our purpose isn’t merely to reduce what harms, but to reclaim what helps. CO₂, once dismissed as industrial exhaust, is now invited back into the fold – captured at the moment of release, refined, repurposed, and revalued. It’s the philosophy of waste to wealth, embedded deep into our engineering.

As our FMD Ravi Varma affirms,

“Our vision of making a difference for a better tomorrow drives us every single day. Guided by this commitment, Hypro continues to innovate & lead sustainability efforts through solutions designed to deliver meaningful ‘Reduction at Source.’ Be it the carbon emission, electrical power, or water consumption.”

This isn’t just sustainability. It’s restorative design. It’s the art of building industries that leave fewer scars – and more signatures of care.

It is our way of showing reverence to the environment – not as a background to business, but as its foundation.

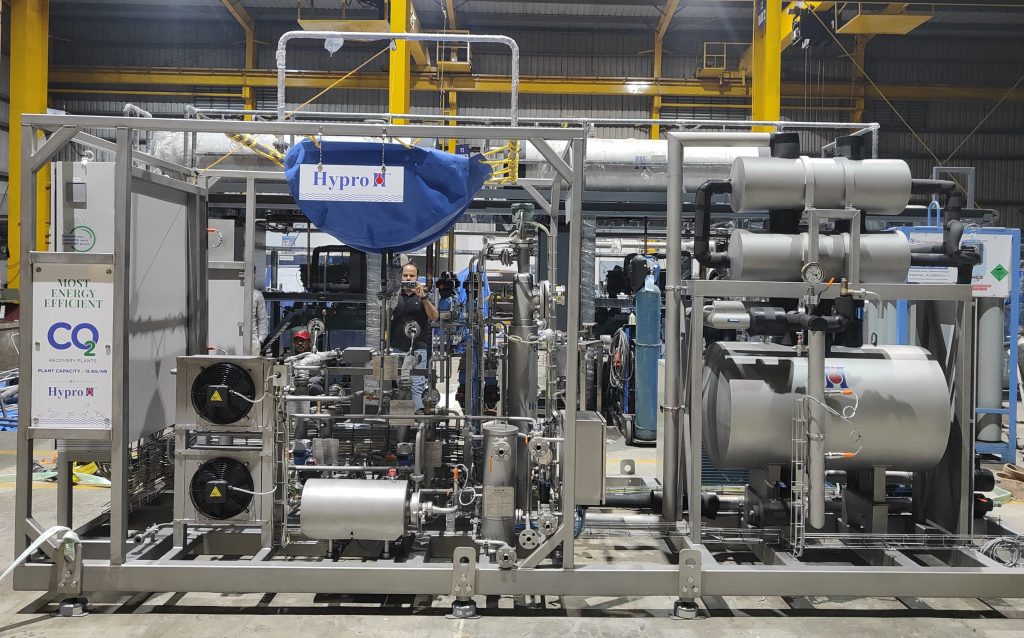

It begins, quite literally, at the source. Hypro’s CO₂ recovery systems are engineered to intercept emissions in their very moment of birth – not at the end of the pipeline, but at the heart of the process. Whether from fermentation tanks, distillery stacks, or biogas domes – we recover what was once lost, and give it new purpose.

This is not the future of industry.

This is what industry must become – thoughtful, circular, and deeply aligned with the rhythms of the environment we depend on, and must now protect.

Across Borders, Within the Environment - Hypro’s Circular Footprint

In a world increasingly aware of its own exhaust, the question is no longer if we should act, but how far we’re willing to go. At Hypro, our answer has always leaned toward regeneration – not just reducing carbon’s footprint, but reinviting CO₂ into the loop, thoughtfully, purposefully, and with deep respect for the environment we share.

It began, quite naturally, with breweries – the heart of fermentation, where carbon is born with every bubble of yeast. In India, Hypro didn’t just enter the brewery CO₂ recovery space – it quietly became its standard, capturing nearly 85% of the market with technologies trusted across the nation. From there, the circle widened. Across Asia, Africa, Europe, the United States, and Australia, Hypro’s systems have followed the path of fermentation, transforming CO₂ from waste into wealth.

From Cambodia’s 1200 kg/h recovery plant at Ziemann Holvrieka to the frost-clad tanks of Moscow, where dual 1000 kg/h units stand under execution – each installation tells a story. Nepal, Myanmar, Sri Lanka, and beyond – these are not just points on a map, but places where what once vanished into the sky is now returned to purpose. There’s a quiet beauty in that cycle, one that respects not only chemistry, but ecology.

Yet even among the brewery projects, some stories stand apart.

In the United Kingdom, at Blunrock Brewery, a compact 15 kg/h CO₂ recovery plant gained national attention, even earning a spotlight feature on BBC – not for its size, but for its symbolism. In an era where sustainability headlines are often dominated by giants, it was this modest craft brewery – with just 1 MT of storage – that showed how every molecule counts when the will is strong.

Across the Atlantic, in Cincinnati, USA, our 1100 kg/h recovery system hums quietly inside Samuel Adams’ craft facility — a sign that American brewing heritage, too, is now steeped in carbon consciousness.

And further south, on the sun-drenched coast of Australia, a different kind of story began to brew. At Coopers Brewery, tradition met transformation when a 500 kg/h CO₂ recovery system was installed – not just to reduce emissions, but to preserve purity.

“After collecting 13 MT, we now have CO₂ onto the brewery. We have checked the flavor, and all is well. The purity is 99.999% v/v… fantastic.”

What began as a sustainability measure became a quiet breakthrough — where green innovation upheld not just quality, but deepened trust in every pour. In a land long driven by extraction, Hypro’s presence now marks a chapter of restoration, one recovery cycle at a time.

But the environment doesn’t limit itself to tradition – and neither do we.

In the highlands of Switzerland, a silent revolution ferments beneath the surface. At Neustark AG, our systems recover CO₂ at 300 kg/h from biogas, not beer – a shift that proves recovery can thrive even in the core of waste. Nearby, in Germany, Greenlyte Carbon Technologies operates a plant that pulls 8 kg/h of CO₂ directly from ambient air, storing it in 150 L tanks – one of Hypro’s most delicate balances of precision and purpose. To work with the air itself – to harvest its excess, not just endure it – is to move from passive mitigation to active care.

We’ve gone further still. In Oman’s arid stretch, where the heat humbles steel, a Direct Air Capture unit breathes quietly, recovering 8 kg/h of CO₂ into a 150 L storage – proof that even the desert can be drawn into the recovery loop. In Kenya, amidst tectonic lands and volcanic soil, our 15 kg/h plant for Octavia Carbon helps pull CO₂ from the very air – a delicate choreography of nature and engineering. These are not just recovery systems – they are philosophies materialized, acts of environmental restoration disguised as infrastructure.

Even distilleries, long haunted by the silent escape of carbon, have begun to breathe differently. In Turkey, where continents meet over ancient soil, a 650 kg/h plant captures CO₂ with quiet precision – a modest rebellion against the long-held norms of industrial release.

Further east, in Azerbaijan, at A+CO OJSC, a 300 kg/h recovery system hums beneath the Caspian winds. Here, on the edge of Europe’s forgotten frontier, Hypro builds not just a plant, but a presence – proof that carbon consciousness is not confined to capitals.

Across these geographies – from Mauritius to Moscow, Estonia to Australia – Hypro has laid down a quiet grid. Not of wires, but of will: a will to close the loops industry once left open, to build systems that give back, not just take. And while the brewery remains our soul – with dozens of installations, from Bhutan’s compact 50 kg/h system to Uganda’s 1500 kg/h giant – the future lies in this diversity of recovery.

Because the environment is not an external place. It is the air in our lungs, the silence between machines, the echo that returns when industry remembers to listen.

Reflection – Beyond Technology: The Human Choice

In a world driven by metrics and machinery, it’s easy to believe that progress is only made in kilowatts and capacities. But true sustainability is not built in metal and equations alone – it begins in intention.

At Hypro, every pipeline is more than a conduit. Every tank, more than steel. They are, in essence, gestures – quiet, deliberate acts of care. A brewery somewhere in the world may recover just 8 kg/h of CO₂, but in that humble volume lies a choice: to act when one could ignore, to restore when one could simply reduce. Large or small, it is the choice that matters – the will to build something better, not just bigger.

Because what we recover isn’t just gas – it’s trust. In the environment’s resilience. In our ability to course-correct. In a future that values balance over speed.

On this World Environment Day, we don’t just mark milestones. We reaffirm the question that guides us daily:

What kind of world are we building – not just for ourselves, but for those who will never know our names, only our choices?

For us, the answer is quiet but firm. We build systems, yes. But more than that,

we build promises – to the earth, to each other, to the generations that follow.

Because to care for the environment is not to fix what’s broken.

It is to remember what’s sacred.

Final word

Let carbon find its way home.

Let industry learn to exhale with grace.

In every loop we close, in every molecule returned to purpose, we write a quieter, wiser future – one where the environment is not something we protect from ourselves, but something we protect within ourselves.

Related Posts

Engineering Sustainability

Hypro believes Earth Day is more than a moment - it’s a mission. From sustainability-driven innovations to CO₂ recovery and digital transformation, discover how Hypro...

Read More