Most Energy Efficient

CO2 Recovery System

CO2 recovery systems by Hypro ensure efficient CO2 recovery from diverse sources, enabling industries to become self-sufficient in their CO2 supply. Carbon dioxide gas is generated across various industries, including breweries, distilleries, wineries, biogas plants, chemical processes, and more.

Our Most Energy Efficient (MEE) CO2 recovery system utilizes indigenously developed technology, constantly upgraded with innovative features for improved performance. With a focus on ease of operation and minimal maintenance, Hypro delivers reliable systems for CO2 recovery enabling long-term operational efficiency across multiple sectors.

Hypro made CO2 Recovery System viable for various sources

Brewery

Winery

Distillery

Chemicals

Enriched Biogas

Enriched Direct Air

Supercritical Extraction

Revert Gas

Eliminating the civil work on your site. Hypro launched a containerized solution for

hassle-free installation.

Hypro prioritizes energy savings through cutting-edge engineering and design in our CO2 recovery system,

making it the ideal choice for industries seeking sustainable solutions.

01

Product Description

Hypro’s CO2 Recovery System including piping are necessarily produced with Stainless Steel as a material of construction. The exception being the liquid CO2 storage tank which is made in low-temperature carbon steel. This provides the plant a long life and often eliminates rust and impurities from the corrosion of carbon steel piping. The absorbers, scrubbers, strippers, distillation columns are provided with high-efficiency structured packing as a standard.

02

Functionality

CO2 Recovery System collects CO2 gas from the fermentation process. CO2 then passes through a series of purification processes and stored in a gas balloon. The gas washer removes the water solubles which is followed by the deodorizing process of CO2 gas compression. Further volume reduction is done in the liquefaction and stored in the CO2 storage tanks.

03

Features

- 150 kg/hr and above Liquid CO2 produced

- The guaranteed output quality of CO2 – 99.998 % v/v

- Special structured packing in Stainless Steel 304L material

- Odor treatment of CO2 to produce Food Grade CO2

- Optimal Pressure: 16-18 Bar g for efficiency

- CO2 Condenser with an arrangement to vent the non-condensable from time to time

- CO2 Gas Compressor with special material for moist CO2 application

- Optional add-on HySAAA module for plant and maintenance management with MIS reporting

04

Advantages

- PLC operated fully automatic with remote access

- Trouble-free operation

- Lower maintenance

- The attractive payback period on capital expenditure and is benefited in longer-term with the lowest operating cost

- Collection systems are sized for ultra-low pressure drops thereby reducing energy requirements

We would love to see you on social media!

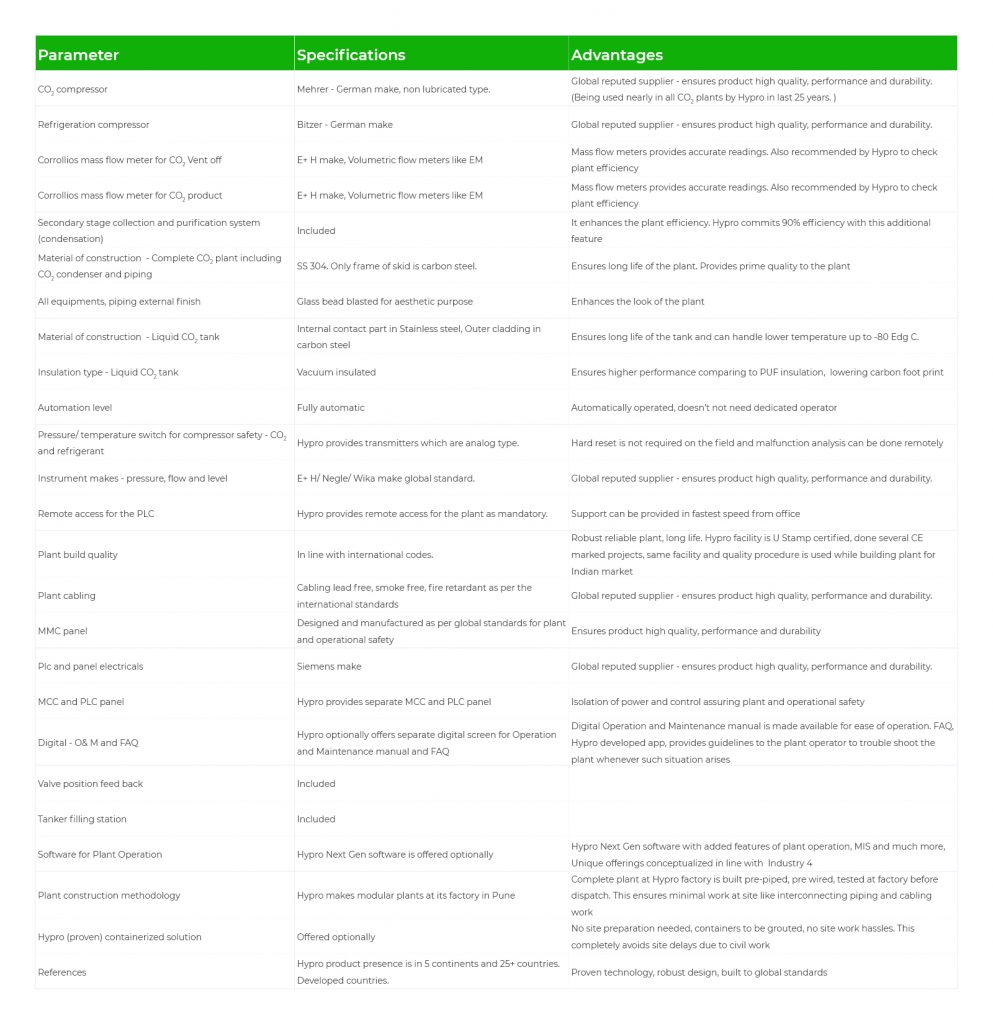

CO2 Recovery Plant Specifications

Compare with similar products

Hypro HyCrCTM Plant

- 15 kg/hr and above Liquid CO2 produced

- Recovers CO2 from Micro/Pub/Craft Breweries

- Ideal for small scale production

MEE CO2 Recovery System

- 150 kg/hr and above Liquid CO2 produced

- Recovers CO2 from Breweries, Distilleries, and Wineries

- Ideal for large scale production

Supercritical CO2 Recovery Plant

- Up to 700 kg/hr CO2 produced

- Ideal for Supercritical Hops Extraction

- Ideal for large scale production

Frequently Asked Questions

CO2 is required for the carbonation of the beer which is an essential step in beer brewing as it forms the beer bubbles.

An ideal way to achieve pure CO2 is to utilize carbon dioxide from your own source. CO2 is produced during fermentation in beer making. Why not recover the CO2 from your own brewery which guarantees perfect quality control – a benefit that no other source can offer.

Continuously changing climate conditions have a potential demand to alter traditional brewing practices that have been passed down to generations. CO2 Recovery is a necessary practice that should be implemented by not only Industrial breweries but also Microbreweries in order to reduce carbon emissions and thereby save mother earth.

The recommended CO2 pressure range is between 7 to 38 PSI depending upon the style of the beer such as Ales, Lagers, Pilsners, and Stouts, etc. An inaccurate pressure may result in under or over carbonation. This may have adverse effects like flat or overly foamy beer.

Often Combined with

A few bottles of imported lager might add up to a tonne of CO2 per year – equivalent to around 50,000 cups of black tea. Hypro offers a sustainable solution for your brewery. We have successfully commissioned an industrial brewery combined with MEE CO2 Recovery System and made the breweries self-reliant on CO2 supply, all the while contributing to the greener earth.