Deaerated Water Plant

Launched in 2018

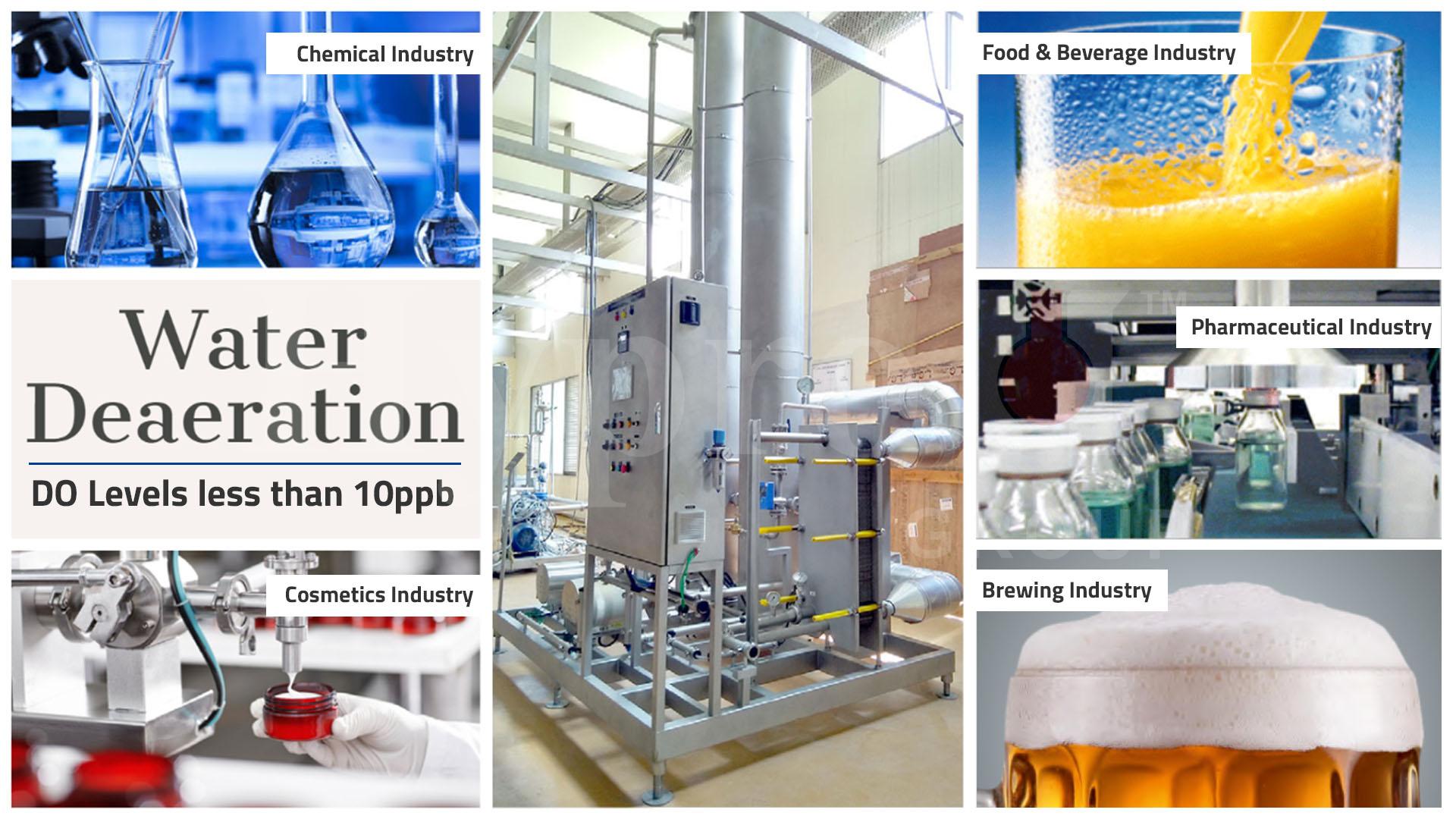

This is now an additional product offering from Hypro apart from its mainstream products. State-of-the-art, Water Deaerator, is the newly launched product to be added to the list of highly innovative products by Hypro. We are now all set to serve multiple industries as our Water Degassing Process is in tune with Brewing, Food & Beverage, Cosmetics, Chemical, Pharmaceutical industries. Being India’s leading international standard hygienic process systems supplier, we have successfully commissioned 5 Water Deaeration Systems for United Breweries Limited. DAW Industrial Plant is conceptualized and designed to reach appreciably lower DO levels in the feed water.

In breweries, it’s a common occurrence that the Brewhouse, which uses steam is not in production mode BUT in the cold cellar operations are in production mode. In such instances, the brewery has to run the boiler to produce steam which was essential to generate deoxygenated water at elevated temperatures. But now no more. Don’t run your boiler at its fractional capacity to generate Deoxygenated water at elevated temperatures. Hypro has a solution that will save you steam energy and use heat energy in the right manner.

We would love to see you on social media!

01

Product Description

Degassed water has high importance in beer tanks & beer supply lines as air/oxygen may spoil the perishability and taste of the Beer. It is therefore so important to achieve DO levels of feed water less than 10 ppb. Who other than Hypro can do it! Hypro fabricates a highly innovative Deaerated Water Plant of global standards. The structure is used to reduce the oxygen content in feed water which is then supplied to the brewhouse. It also produces brewing-quality water which is used to dilute the beer in the high-gravity brewing process. DAW System consists of a deaerator column with high efficiency structured packing inside it. We have also eliminated the use of steam energy for our Water Deaeration Systems.

02

Functionality

Feed water for which oxygen content to be removed & CO2 sweep gas is passed in a counter-current manner through deaerator column. The mass transfer takes place through the packing resulting in a dissolve of oxygen into CO2 sweep gas. This water will get then pass through the glycol-based heat exchanger. This will chill the DAW water to 3 deg cel & further stored in DAW storage tank, further transferred to the brewhouse.

03

Features

- DO levels less than 10 ppb at nearly 70 Deg C

- Eliminate the need of using steam completely

- Capacity starts from 15 hl/hr

- Produces Blend Water for high-gravity beer brewing

- Deaerator column with high efficiency structured packing inside

04

Advantages

- Semi-automatic and/or fully automatic system

- Low energy costs

- Low commissioning costs

Frequently Asked Questions.

The hardness of the water is determined by Calcium – a principle mineral which in turn, contributes to the flavor and clarity of the final brew.

The purpose of a deaeration is to reduce dissolved gases particularly oxygen as O2 is the enemy of a good quality beer. In addition, it also improves plant thermal efficiency by raising the water temperature.

The height ensures a predetermined lower pressure given by the liquid column. Tank working at a lower pressure makes its less critical sealing problems.

The importance of deaerated water in beer brewing cannot be overstated as water constitutes about 95% of the total ingredients. Hypro provides an innovative yet affordable solution to deaerate the feed water for your brewery. DAW plant by Hypro achieves DO levels less than 10 ppb, unlike conventional systems.

Often Combined with

Setting up a Brewery but worried about Feed Water Treatment? Hypro has got an innovative solution that is totally customized as per your needs. That is to say, DAW Plant is the perfect fit for your wishlist along with the Industrial Brewery in order to generate oxygen-free feed water.