#coal #PowerPlant #CO2 #sustainability #carbonfootprint

Advances in Coal-fired Power Plant Emissions Control Technologies

Coal-fired power remains a cornerstone of global electricity generation, supplying approximately 36% of the world’s electricity demand as of 2023 (IEA). Particularly in emerging economies where energy security and affordability are paramount, coal-fired facilities continue to play a pivotal role in stabilizing national grids and meeting industrial load requirements.

Against a backdrop of intensifying climate commitments, tightening regulatory frameworks, and escalating stakeholder expectations – from investors to consumers – emissions control in coal-fired operations is no longer optional. It is a strategic imperative shaping the future viability of coal as an energy source.

To understand how the industry is responding to this challenge, we must first examine the core pollutants emitted by coal-fired plants and the control strategies being deployed to mitigate their impact.

Emissions profile of coal-fired facilities

Coal-fired facilities remain among the most scrutinized industrial sources of atmospheric emissions. A precise understanding of their emissions profile is essential for formulating effective control strategies that address both regulatory compliance and environmental sustainability.

The flue gas emitted from coal-fired plants comprises a complex mixture of gases and particulates, dominated by carbon dioxide (CO₂) – the principal greenhouse gas driving climate change. On average, a conventional coal-fired facility emits approximately 820–1050 g CO₂/kWh, depending on the plant’s efficiency and the coal grade used (IEA, 2021). CO₂ constitutes roughly 70–80% of the total flue gas volume.

Accompanying CO₂ are significant levels of sulfur oxides (SOx), primarily originating from sulfur compounds inherent in coal. Emissions can range from 2–6 g SO₂/kWh, highly contingent on the sulfur content of the feedstock. Nitrogen oxides (NOx) – formed through high-temperature combustion reactions – typically register around 1–3 g NOx/kWh. These gases contribute directly to acid rain, ground-level ozone formation, and respiratory ailments.

Particulate matter (PM), predominantly in the form of fly ash and unburned carbon residues, poses another serious concern. Without emission controls like electrostatic precipitators or baghouse filters, PM concentrations in flue gas can reach 50–150 mg/Nm³. Additionally, trace elements such as mercury (Hg), arsenic, and volatile organic compounds (VOCs) further compound the environmental footprint of coal-fired operations.

Emission volumes from coal-fired facilities are influenced by several factors:

- Coal type – Bituminous and lignite coals differ significantly in sulfur and ash content

- Combustion technology – Pulverized coal, fluidized bed, or IGCC systems each impact emission characteristics

- Plant efficiency – Ultra-supercritical plants emit less per kWh than subcritical counterparts

Given that coal-fired plants accounted for ~30% of global CO₂ emissions from fossil fuel combustion in 2022 (IEA), their emissions profile remains a focal point for control measures worldwide.

Advanced emissions control technologies in coal-fired power plants

Over the decades, a suite of advanced technologies has evolved to mitigate harmful emissions from coal-fired power plants. These solutions target sulfur oxides (SOx), nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO₂), contributing to more sustainable plant operations while complying with tightening environmental standards.

Flue Gas Desulfurization (FGD)

FGD systems are pivotal for controlling SO₂ emissions, removing 90–99% of sulfur oxides from flue gases. The most prevalent configuration is wet FGD, accounting for 95% of global installations (World Bank, 2019). Here, flue gas passes through a slurry of limestone (CaCO₃), which reacts with SO₂ to form gypsum (CaSO₄·2H₂O) – a commercially useful byproduct.

Dry and semi-dry FGD variants exist, but wet systems dominate due to higher efficiency and scalability. Installation costs typically range from $100–250/kW, with operational considerations including slurry management, reagent availability, and byproduct handling.

Electrostatic Precipitators (ESP)

ESPs are highly effective for particulate matter control, achieving 99% removal of even fine PM fractions. The core mechanism involves imparting an electrostatic charge to particles, which are then attracted to oppositely charged collection plates.

Compared to baghouse filters, ESPs handle higher flue gas volumes with lower pressure drop but may exhibit lower efficiency on ultrafine particles (<2.5 μm). Modern ESP systems are optimized with pulse energization and rapping mechanisms for enhanced performance and reduced maintenance. These systems are integral to particulate emissions compliance, particularly in older coal-fired facilities.

Selective Catalytic Reduction (SCR)

SCR systems are the gold standard for NOx control in coal-fired plants, achieving 90–95% reduction. The process involves injecting ammonia (NH₃) into the flue gas stream, which then passes over a vanadium-titanium catalyst bed, converting NOx into benign nitrogen (N₂) and water vapor.

SCR is extensively adopted in Asia and EU regions due to stringent NOx standards. Key considerations include ammonia slip control, catalyst deactivation rates, and operational temperatures (300–400°C) to maintain optimal reaction kinetics and minimize byproduct formation.

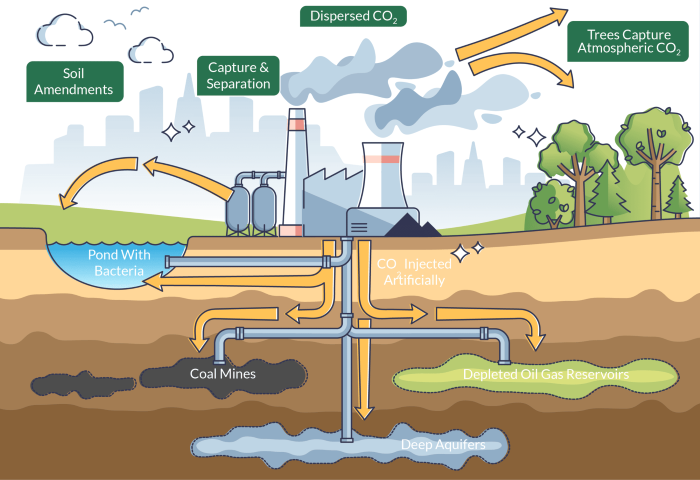

Carbon Capture and Storage (CCS)

CCS technologies aim to capture up to 90% of CO₂ emissions from coal-fired plants (Global CCS Institute, 2022). Post-combustion capture using amine solvents is the most mature route, while pre-combustion and oxyfuel combustion approaches offer alternative pathways.

Notable projects include Boundary Dam (Canada) and Petra Nova (USA), which have demonstrated commercial-scale feasibility. However, challenges persist – capture costs range from $60–120/ton CO₂, and energy penalties reduce plant efficiency by 15–30%.

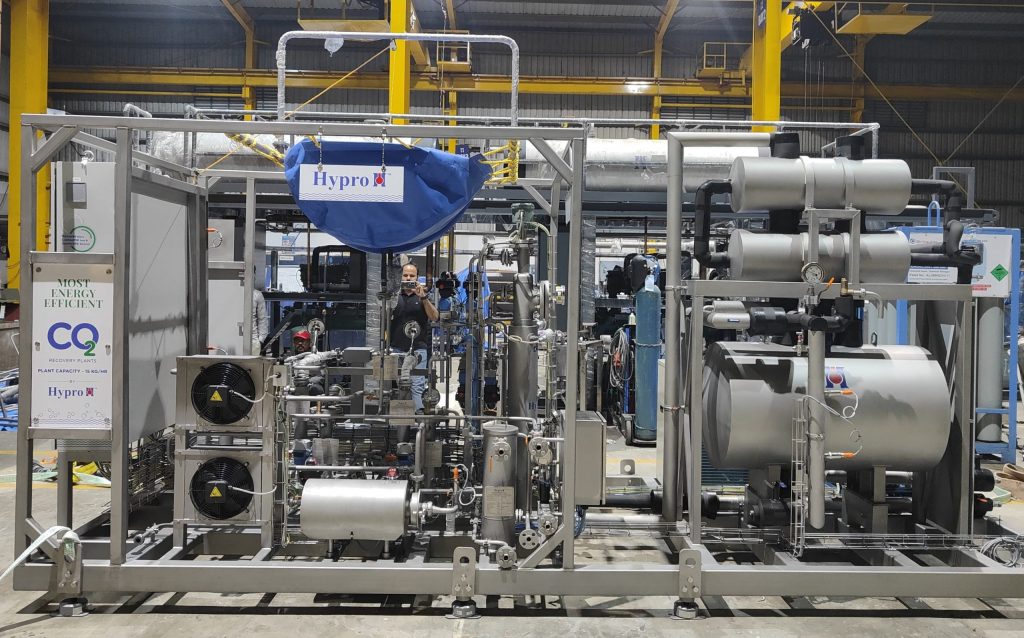

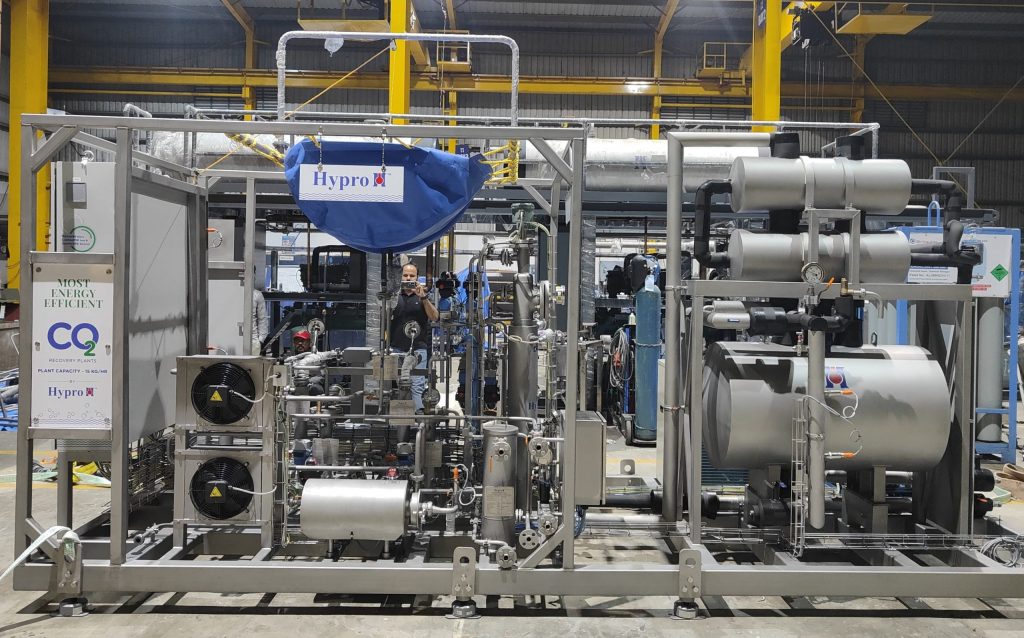

Advancements in membrane-based capture and solid sorbents continue to evolve globally. In parallel, Hypro has engineered integrated CO₂ recovery systems that deliver 99.998% purity with unmatched energy efficiency – directly recovering CO₂ from flue gas streams for commercial application.

Challenges and future outlook for coal-fired emissions control

Despite substantial technological advancements, controlling emissions in coal-fired power plants remains fraught with challenges that complicate both implementation and long-term sustainability.

First, the capital and operational expenditure (CapEx and OpEx) associated with emissions control technologies is considerable. For example, installing flue gas desulfurization (FGD) systems can cost between $100 and $300/kW of capacity, depending on plant size and technology type (World Bank, 2019). Similarly, integrating carbon capture and storage (CCS) can escalate a plant’s levelized cost of electricity (LCOE) by 30–40% due to the significant energy demand of capture systems (IEA, 2021).

Second, retrofitting older coal-fired facilities poses structural and logistical difficulties. Aging infrastructure may lack the spatial and engineering provisions required for new installations, especially CCS units that demand large absorber columns and compression stations. Additionally, emissions control systems often introduce a parasitic energy load – for CCS, this can be 15–30% of a plant’s output, directly impacting efficiency and profitability (Global CCS Institute, 2022).

Third, regulatory and policy uncertainty continues to hinder confident investment. While carbon pricing mechanisms such as the EU ETS and US 45Q tax credits incentivize capture, fluctuating policy landscapes create ambiguity about long-term returns.

Looking ahead, future-proofing strategies are emerging. Biomass co-firing (up to 30%) can reduce net CO₂ emissions, and pioneering trials in ammonia co-firing (notably in Japan) suggest new pathways for decarbonization. Moreover, integrating CO₂ recovery solutions, such as Hypro’s high-purity capture systems, can offset compliance costs by creating revenue streams from food-grade CO₂ sales.

As regulatory pressures tighten and technological innovations mature, operators of coal-fired plants will need to adopt multi-faceted strategies that balance compliance, cost-efficiency, and sustainability.

Innovative CO₂ recovery solutions by Hypro

As industries worldwide intensify their efforts to decarbonize, advanced CO₂ recovery solutions are emerging as critical enablers for cleaner coal-fired operations. Among these, Hypro’s state-of-the-art CO₂ recovery systems have set a benchmark in both performance and efficiency for flue gas treatment.

Designed to recover CO₂ directly from the flue gas streams of coal-fired boilers, Hypro’s plant delivers an exceptional purity level of 99.998% v/v, qualifying the recovered CO₂ as food-grade. This ultra-pure CO₂ finds immediate application across diverse sectors – including beverage carbonation, pharmaceutical manufacturing, and food processing – opening viable commercial avenues for what was once an atmospheric pollutant.

At the core of Hypro’s system lies its proprietary energy-efficient technology, engineered to minimize kWh/ton of CO₂ captured. By optimizing energy consumption throughout the capture, purification, and compression stages, the system not only reduces operational expenditure but also enhances the sustainability profile of the host facility.

Crucially, Hypro’s solution aligns with evolving Net Zero and Environmental, Social, and Governance (ESG) mandates by preventing CO₂ venting into the atmosphere. Instead, it enforces a “recover at source” strategy, capturing CO₂ at the point of emission and transforming it into a usable commodity. This integrated approach supports circular carbon economy principles – where industrial CO₂ emissions are not just mitigated but valorized.

Hypro’s expertise in engineering end-to-end CO₂ recovery plants positions it as a strategic partner for coal-fired facilities aiming to balance operational efficiency with environmental stewardship. For stakeholders exploring emission control pathways that generate both compliance and commercial value, Hypro’s solution offers a compelling, future-ready proposition.

Actionable pathways for cleaner coal-fired operations

As the global energy landscape shifts toward decarbonization, the imperative to control emissions from coal-fired facilities has never been more urgent. For an industry that still underpins over a third of global electricity supply, reconciling operational demands with environmental stewardship is a complex, but necessary task.

The path forward is clear: a comprehensive emissions control strategy that integrates advanced technologies with evolving regulatory mandates. Solutions like Hypro’s CO₂ recovery systems exemplify this dual benefit. By recovering high-purity CO₂ directly from flue gas, such systems transform regulatory compliance into a value-generating opportunity – supporting both environmental goals and revenue diversification.

For industry leaders and decision-makers, the time to act is now. With the right combination of technology, policy alignment, and strategic foresight, coal-fired facilities can transition toward cleaner, more sustainable operations – balancing energy security with environmental responsibility.

Related Posts

CO2 Recovery Power Plant

Power plants are among the biggest CO₂ emitters, but what if they could turn pollution into profit? With advanced CO₂ recovery technology, emissions can become...

Read MoreEngineering Sustainability

Hypro believes Earth Day is more than a moment - it’s a mission. From sustainability-driven innovations to CO₂ recovery and digital transformation, discover how Hypro...

Read MoreEnvironment First

On the World Environment Day, Hypro redefines the role of industry - not as a force that extracts, but as one that restores. With over...

Read More